The PUPSIT is now a must for your automation projects

The PUPSIT is now a must for your automation projects

While it has long been part of the arsenal of measures used in contamination control strategies, the sterile filtration of vaccines and parenteral drugs before the filling stage is a crucial requirement for good manufacturing practices in the pharmaceutical sector. Filter integrity tests before and after production, ensuring sterility, and production data integrity are now at the forefront of all discussions.

As part of a continued commitment to excellence in the biopharmaceutical field, automating the sterile filtration steps is becoming the new standard in this area.

Automated management of test sequences is an essential pillar of compliance with Good Manufacturing Practices (GMP). A user-friendly equipment interface will allow users to plan and execute integrity tests efficiently, thus reducing the risk of human error and ensuring reliable results at every stage of the process.

Another crucial aspect is the ability of systems to precisely regulate the filtration flow rate. This feature allows for a meticulous control of the filtration process, ensuring optimal performance while meeting the strictest standards of the biopharmaceutical industry.

The integration of intelligent filtration stoppage management will ensure responsiveness to potential unforeseen events. This functionality helps minimize production process interruptions, thereby optimizing the overall efficiency of your biopharmaceutical environment.

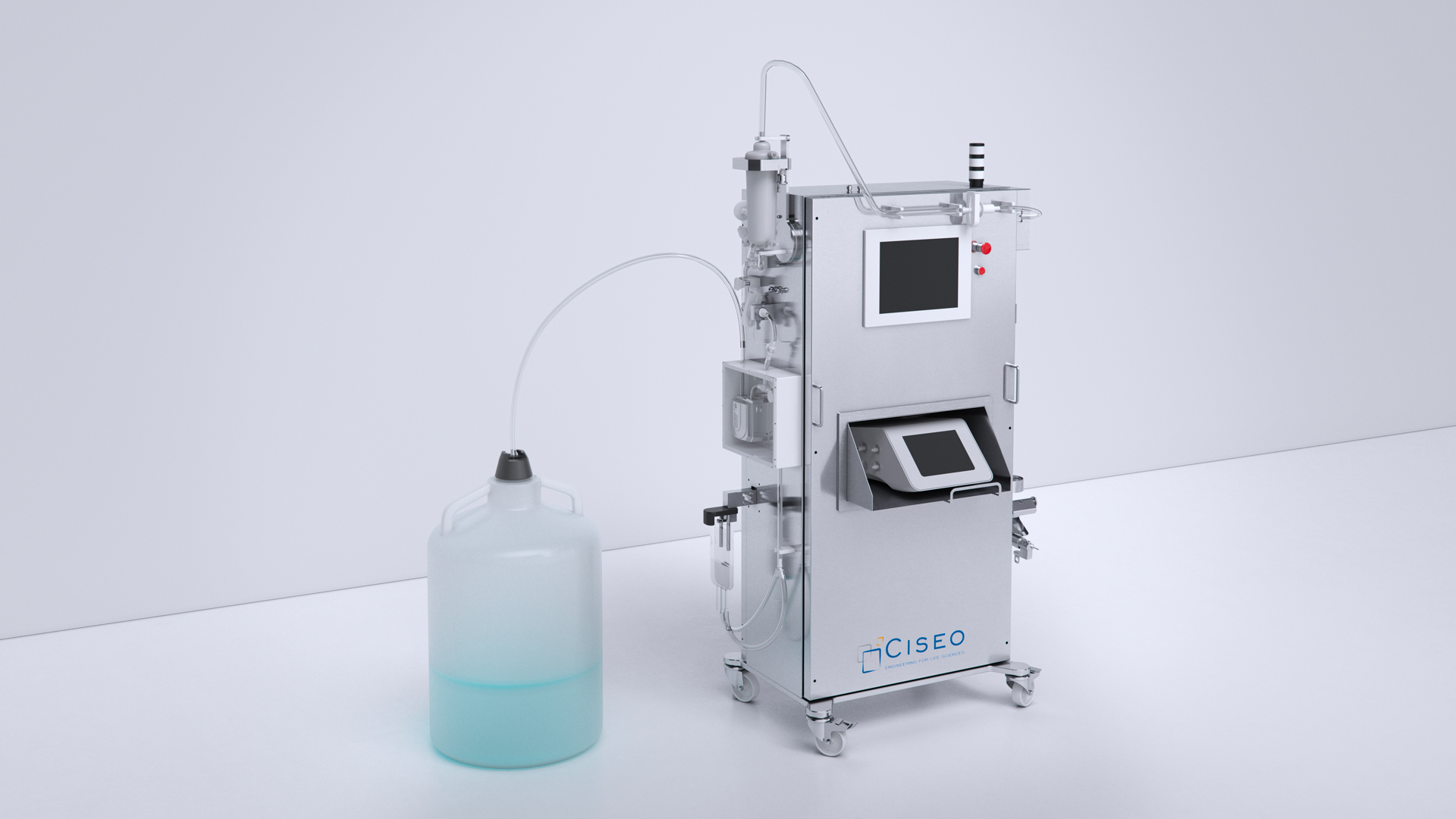

Choosing your sterile filtration equipment is an investment in cutting-edge technology that perfectly adapts to the rigorous demands of the industry. With automated test management, precise filtration flow rate regulation, and efficient stoppage management, our equipment is the ideal solution to ensure the quality, safety, and efficiency of your biopharmaceutical production process.

Click here to learn more about the compliance of our sterile filtration equipment with Annex 1 requirements. Discover how our advanced technology meets the stringent standards for PUPSIT (Pre-use Post Sterilization Integrity Testing) defined by Annex 1 of the Good Manufacturing Practices (GMP) of the European Medicines Agency (EMA). Ensure your biopharmaceutical production process adheres to the highest standards by exploring the specific features of our equipment and its essential role in maintaining the quality and safety of biopharmaceutical products.

A project in mind ? You need to discuss with an expert ?

Take contact with our experts and get personalised advices