Advanced Quality Assurance for Pharmaceutical Implants

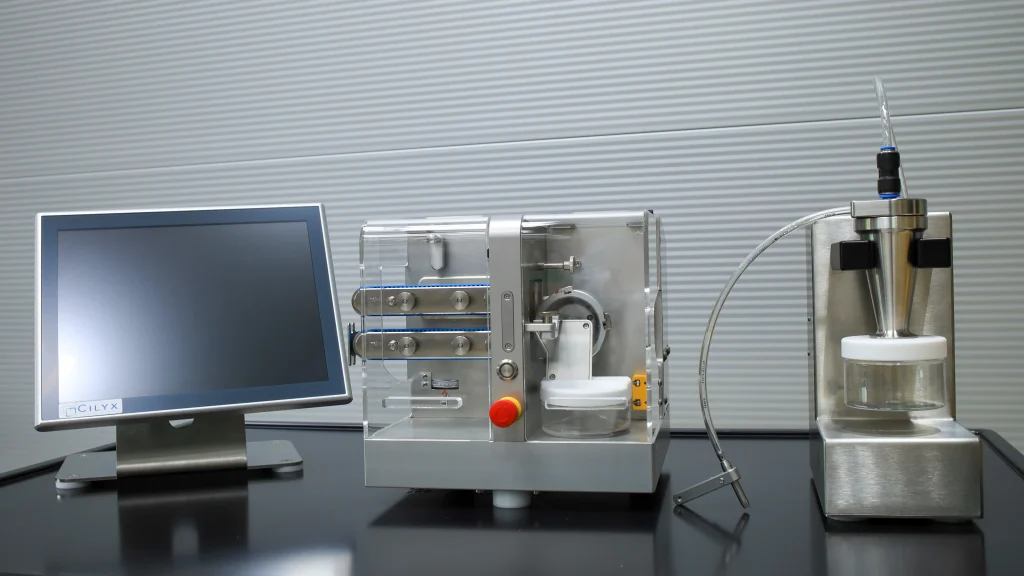

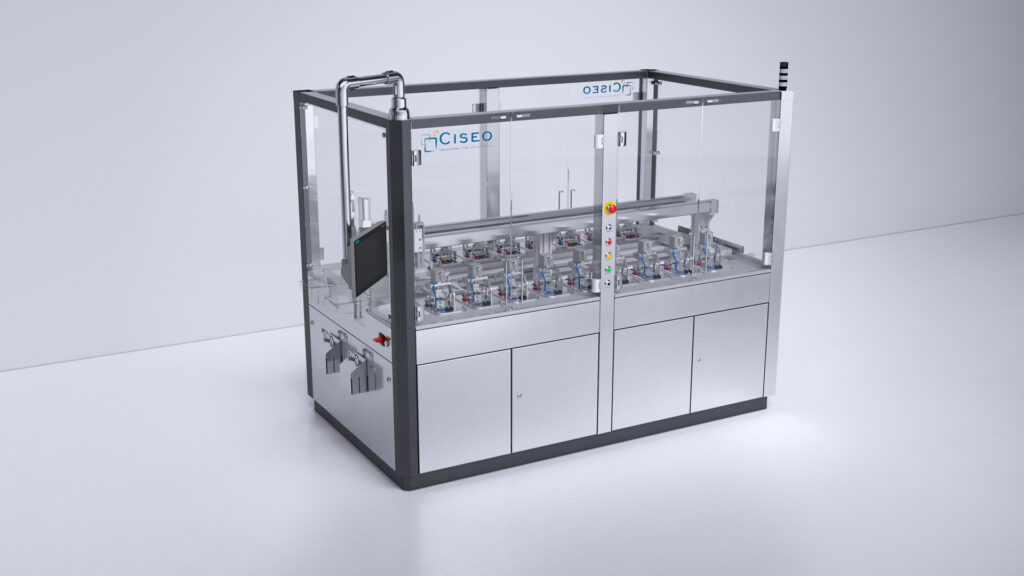

In the pharmaceutical industry, the quality of implants and micro-implants is crucial to ensure the safety and efficacy of treatments. At CILYX, we utilize advanced artificial vision systems to perform rigorous quality control, ensuring that every implant meets the highest standards.

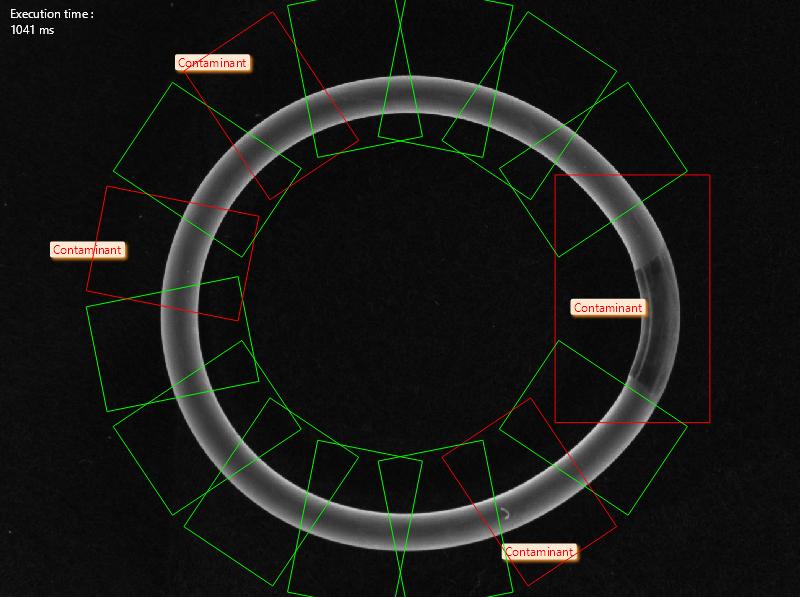

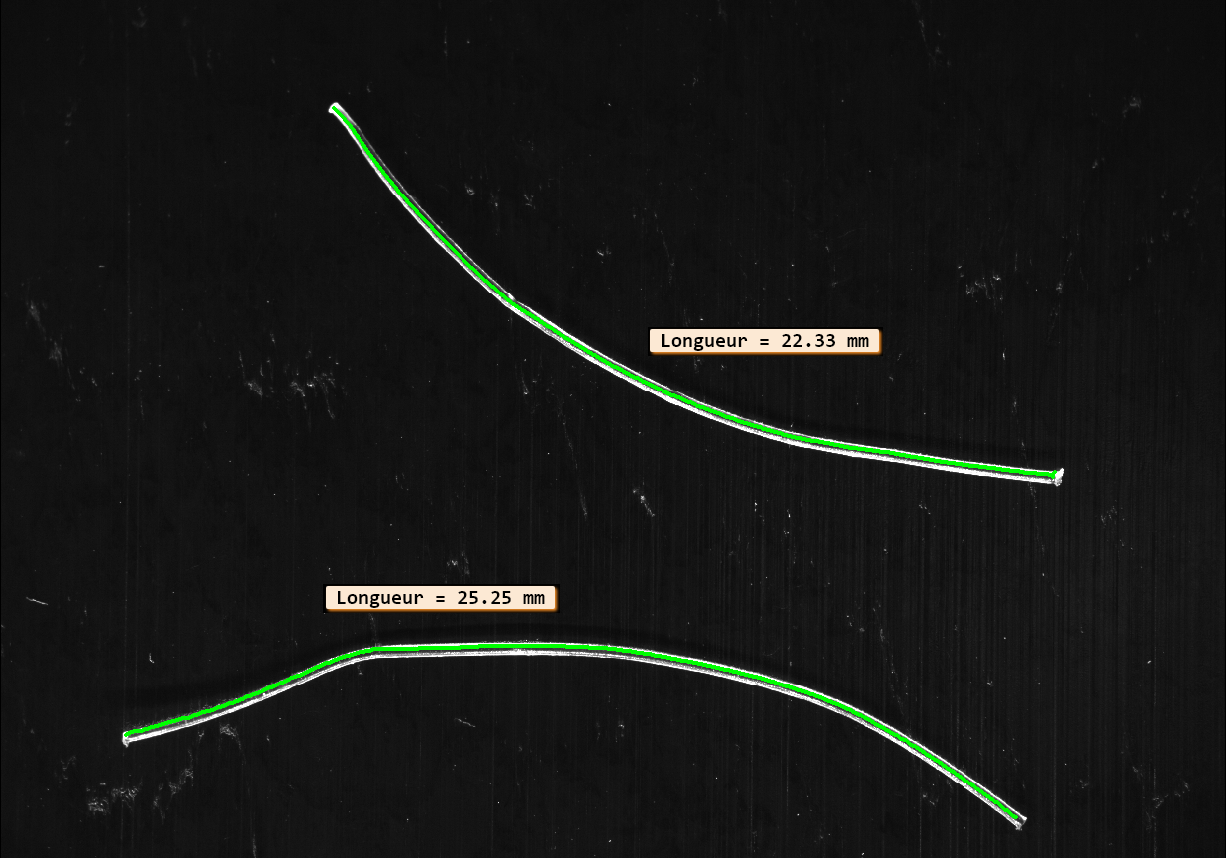

Detection of Dimensional and Cosmetic Defects

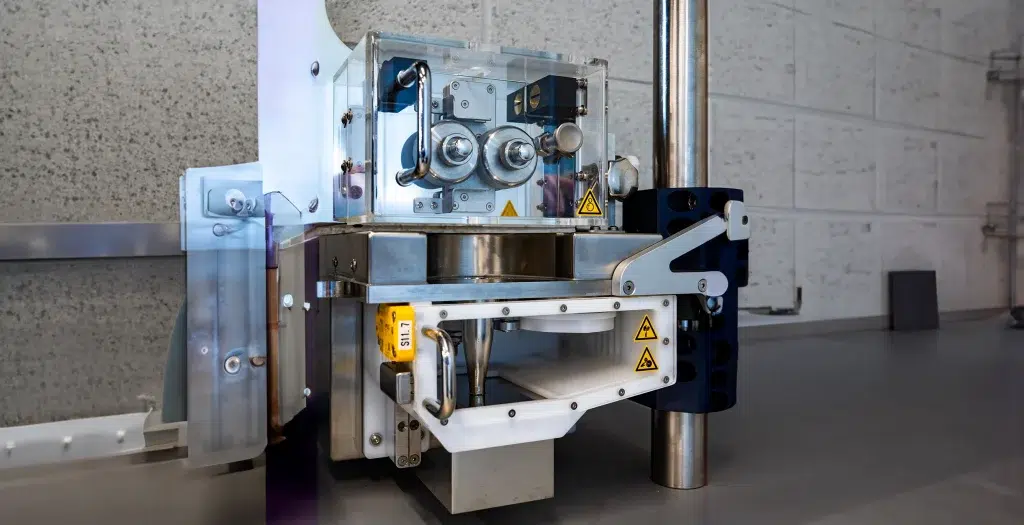

Our artificial vision solutions are designed to quickly and accurately identify dimensional and cosmetic defects. Dimensional inspections verify that each implant or micro-implant meets specified tolerances, ensuring optimal functionality and compatibility with medical applications. Simultaneously, our systems detect cosmetic imperfections such as scratches, deformations, or surface irregularities, ensuring a flawless appearance of the products.

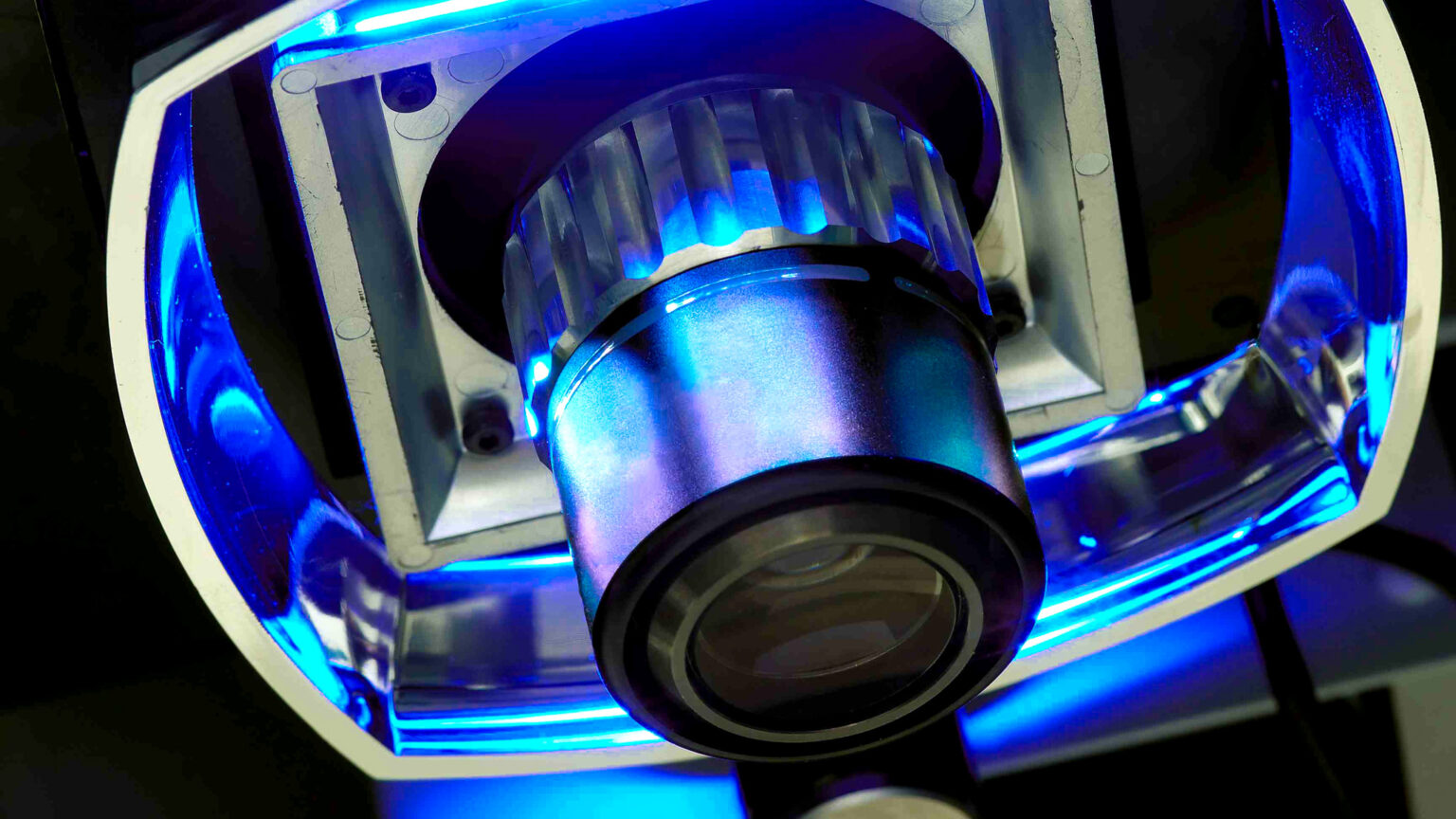

Artificial Vision Technology: Precision and Reliability

With sophisticated algorithms and high-resolution cameras, our artificial vision systems offer a complete and rapid inspection of each implant. This technology achieves an unparalleled level of precision, eliminating human errors and increasing the efficiency of the quality control process.

Optimizing Production Processes

Integrating artificial vision into the quality control of implants and micro-implants optimizes the entire production process. By detecting defects at an early stage, we reduce the risk of downstream rejection, improve productivity, and ensure products comply with the strictest regulatory standards.