Automated quality control refers to the use of technology, such as computers or robots, to monitor and maintain the quality of products or processes.

Automated quality control refers to the use of technology, such as computers or robots, to monitor and maintain the quality of products or processes. This can include things like checking for defects, verifying that products meet certain specifications or standards, and identifying and correcting problems in real-time. Automated quality control systems can be used in a variety of industries, including manufacturing, healthcare, and food processing.

One advantage of automated quality control is that it can be faster and more accurate than manual inspection. It can also help to reduce the risk of human error, which can be a common cause of defects in products or processes. Automated quality control systems can also be more consistent, as they do not tire or become distracted like humans do.

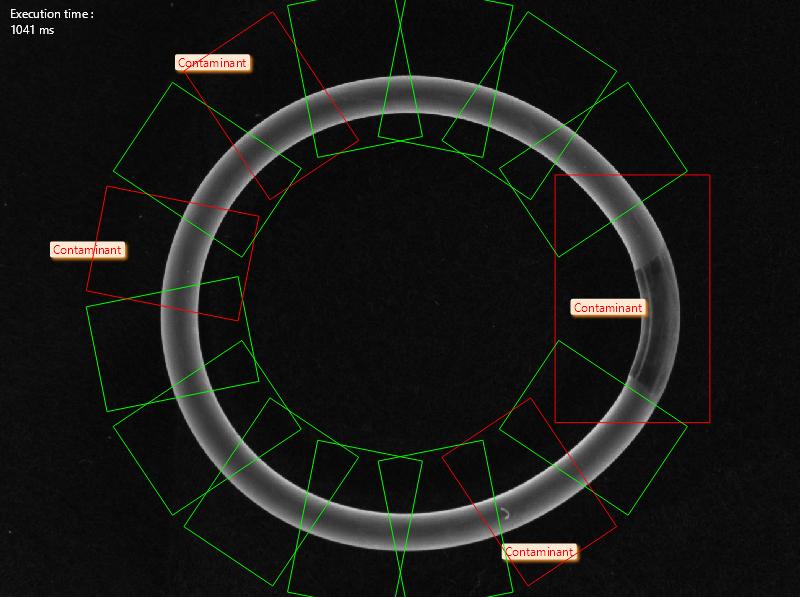

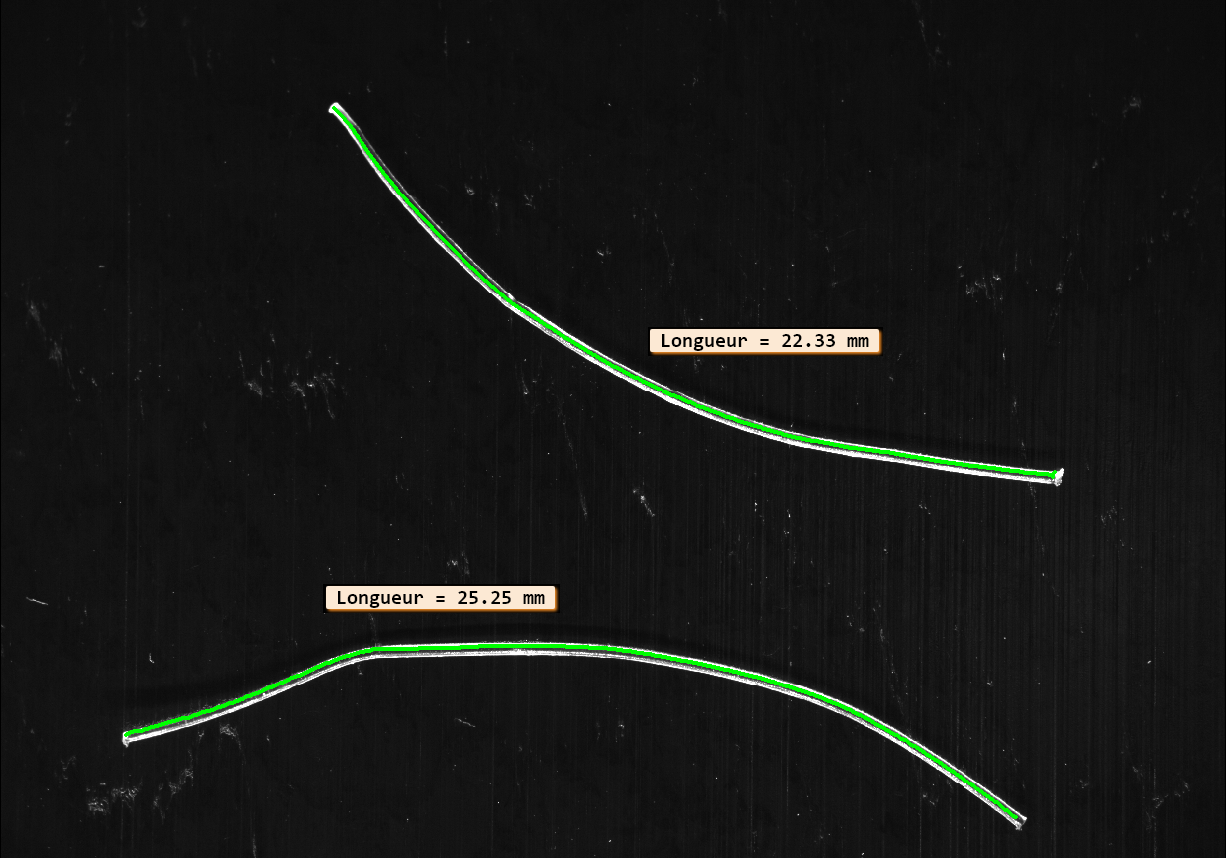

There are several different types of automated quality control systems that can be used, depending on the needs of the specific industry or application. These can include things like machine vision systems, which use cameras and software to inspect products for defects, and robotic systems, which can be programmed to perform tasks like welding or assembly with a high level of precision.

Overall, the use of automated quality control systems can help to improve the efficiency and reliability of manufacturing and other processes, while also helping to ensure the quality and safety of products.