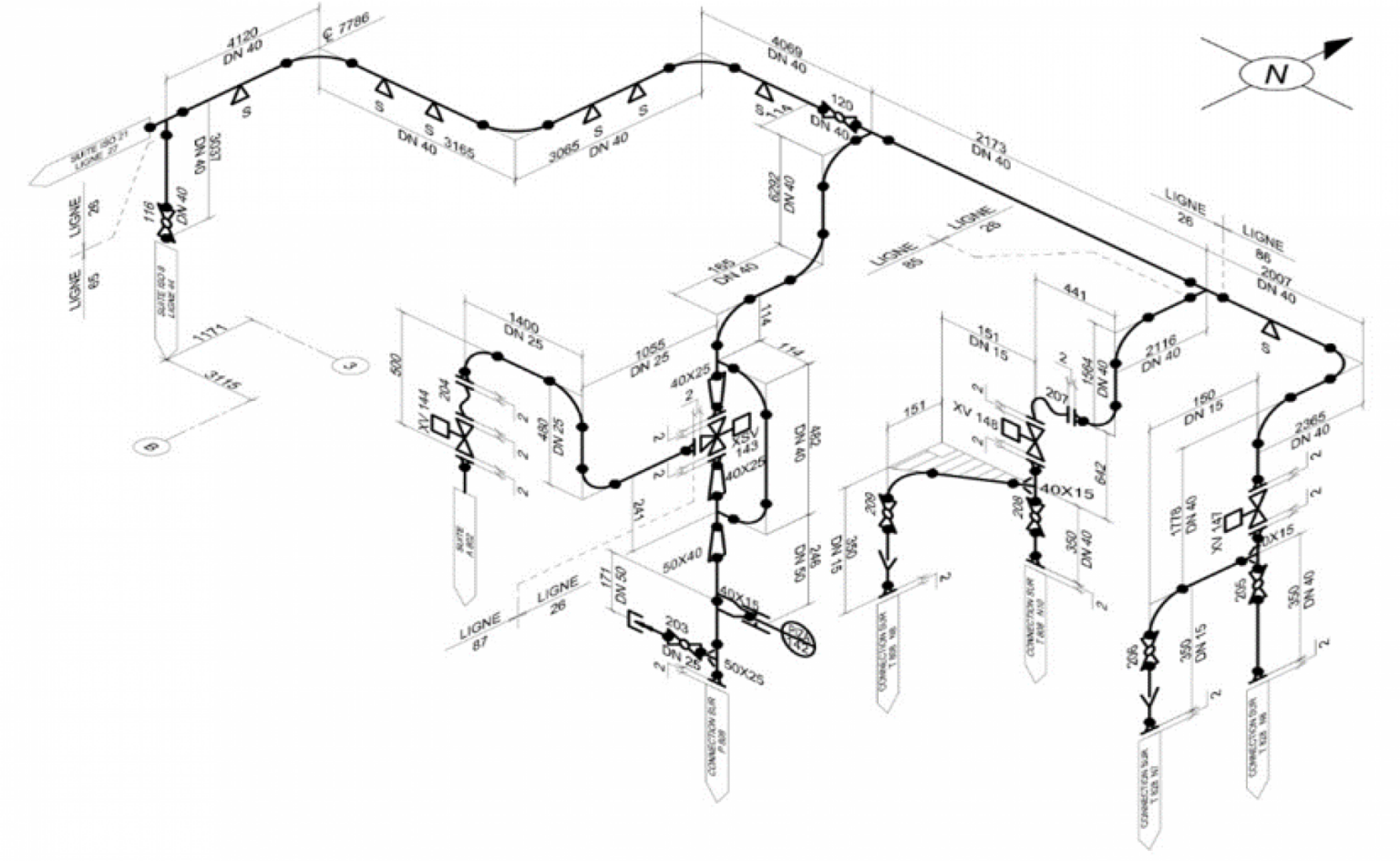

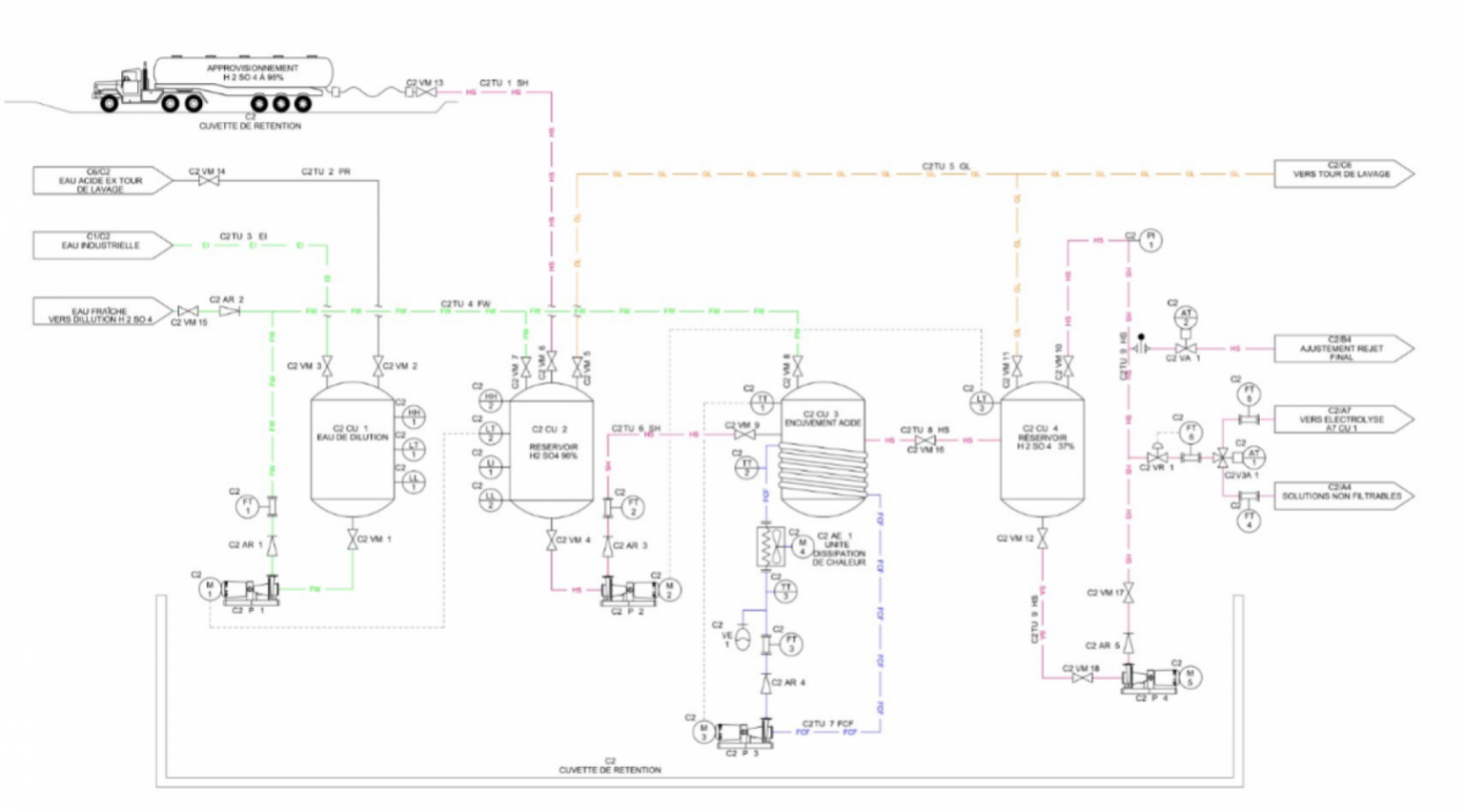

Sizing of piping consists in determining the characteristics of the pipes and associated elements according to the quantity and nature of the fluids to be transported, as well as the operating conditions.

There are several piping sizing methods, which can vary depending on the nature of the fluids and the selection criteria used (cost, weight, size, etc.) but also on the applicable norms and standards. To size a pipe, several parameters must be taken into account, such as:

- The quantity of fluid to be transported: it is necessary to determine the maximum flow rate and the nominal flow rate of the installation, according to the expected consumption and the necessary safety margins.

- The properties of the fluid: it is necessary to know the viscosity, the density and the temperature of the fluid, as well as its chemical composition and its compatibility with the materials of the piping.

- The characteristics of the installation: it is necessary to take into account the working pressure and the discharge height of the installation, as well as the length and layout of the pipes and associated elements.

Piping sizing is a complex area that requires in-depth study and knowledge of fluid characteristics and selection criteria for pipes and associated components.

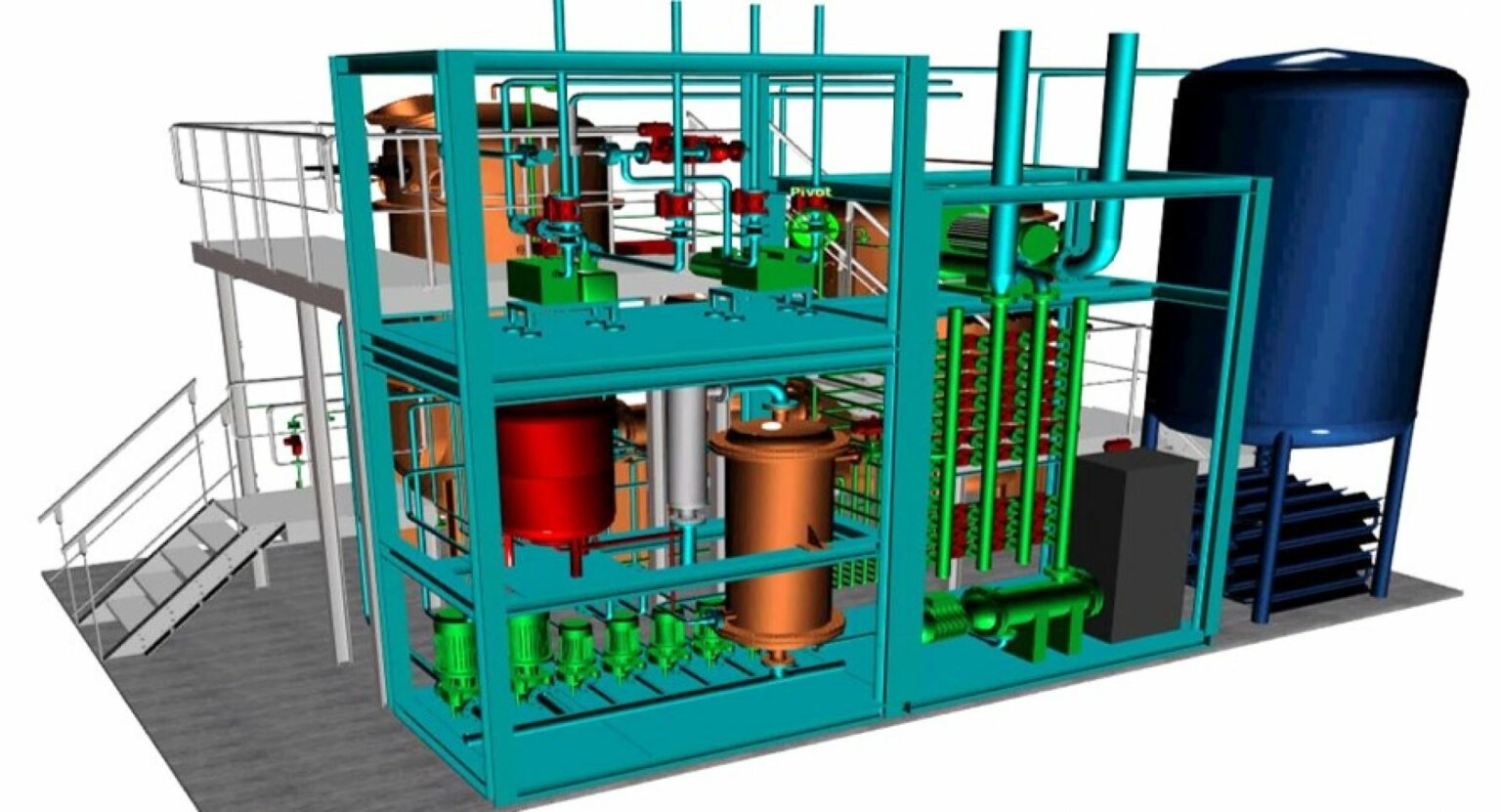

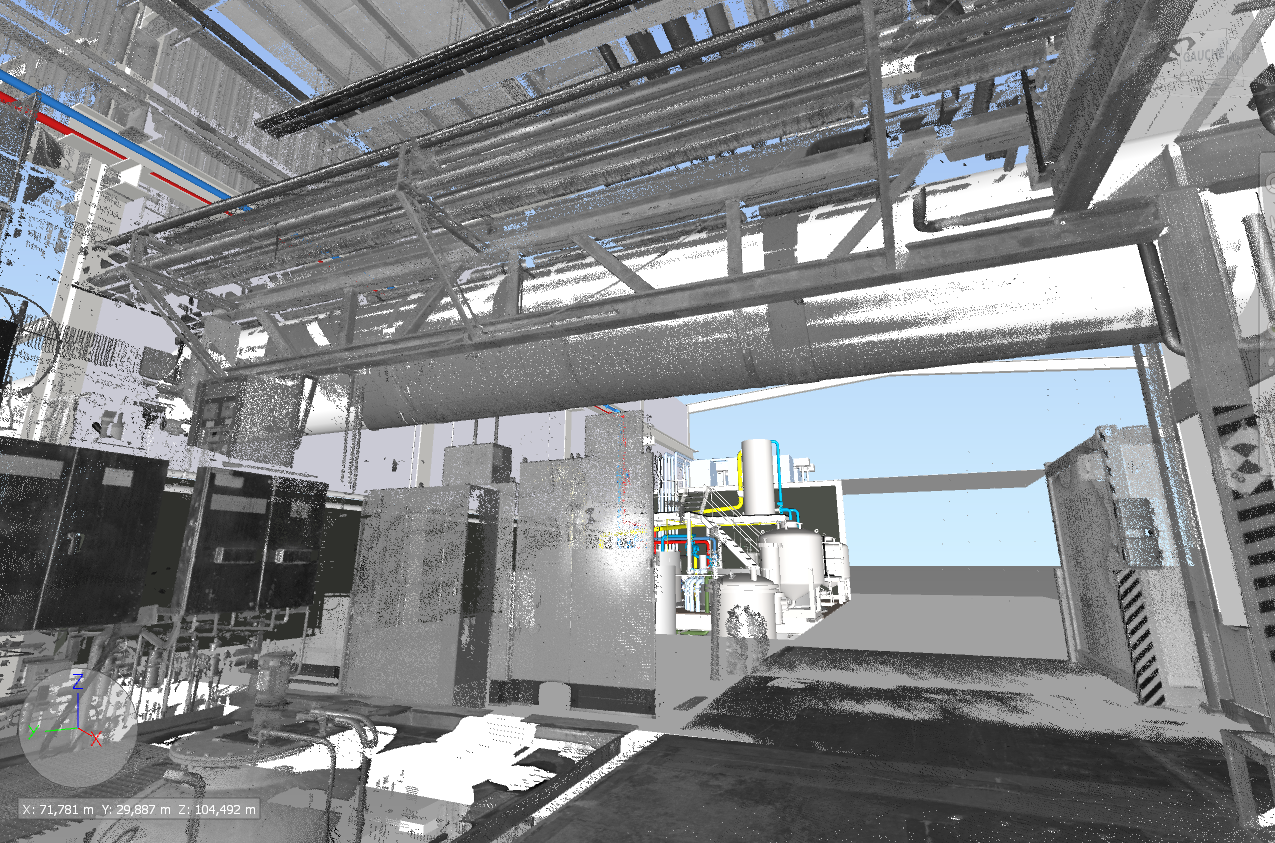

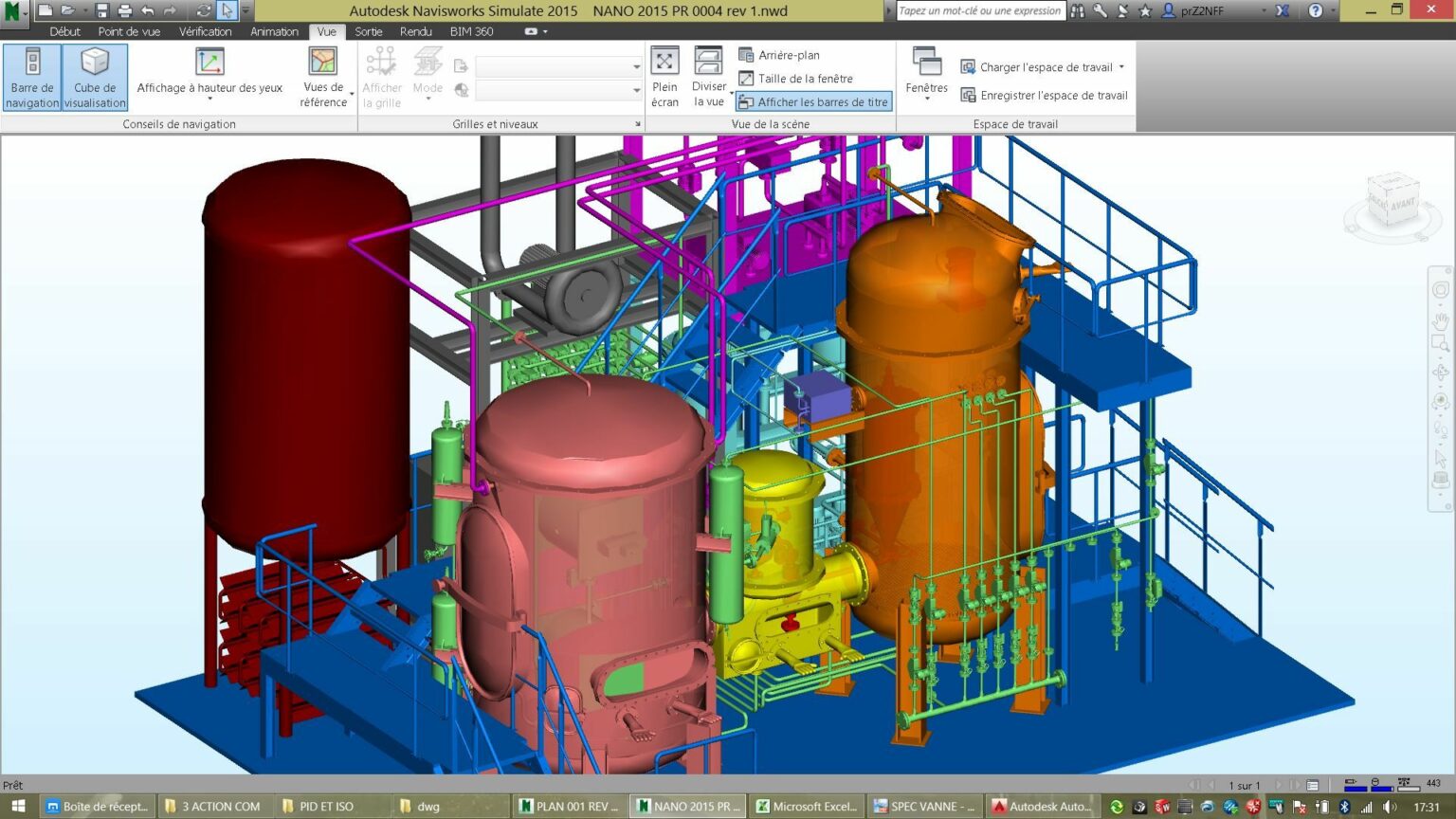

With help of advanced 3D scanning tools one can directly model existing facilities and easily integrate new pipe lines and equipment. this method reduces drastically the engineering and manufacturing time and provide accurate integration results.