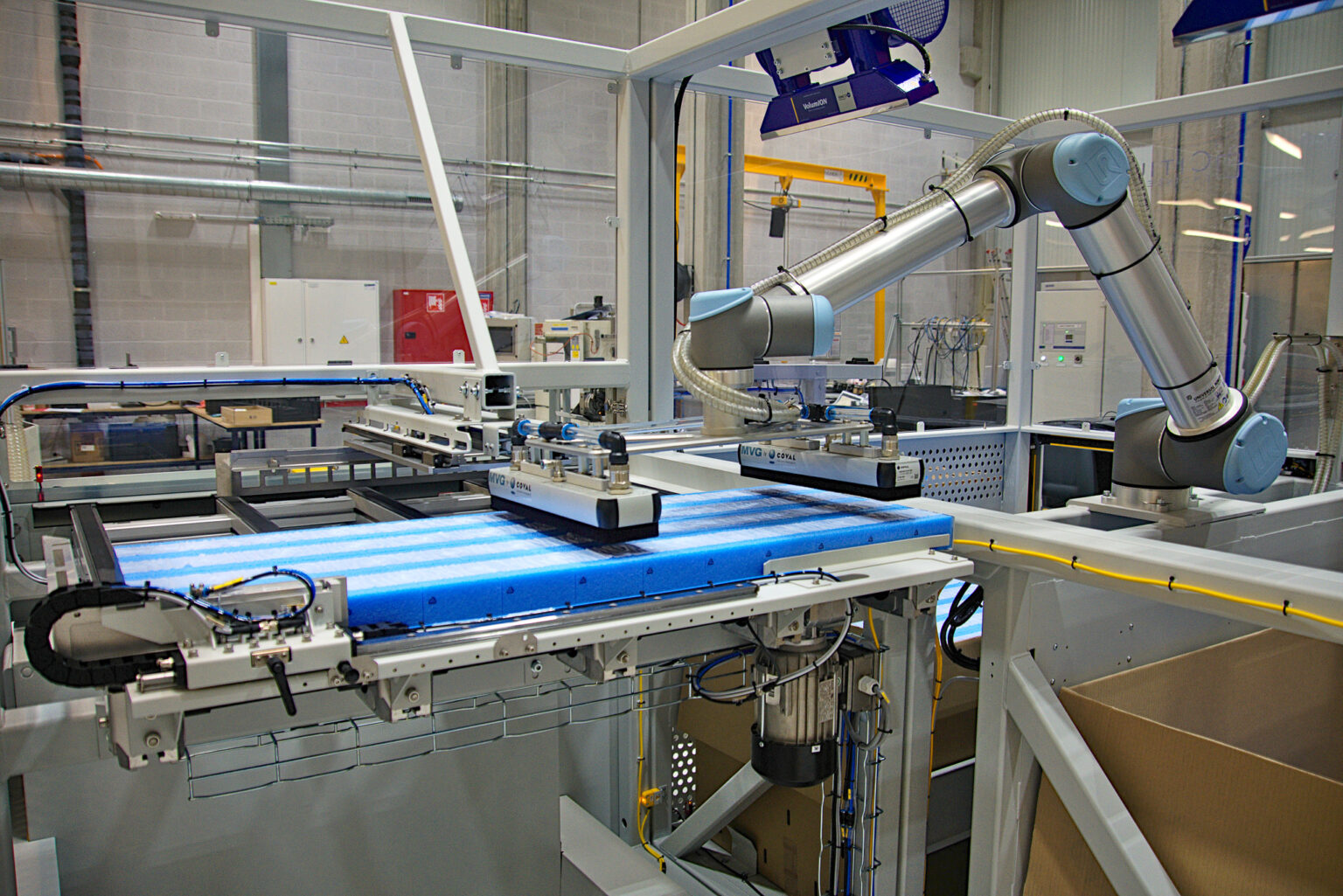

Automated and configurable packaging solution

Automated packaging refers to the use of machines and automation technology to package goods for distribution and sale. Automated packaging systems are designed to be fast, efficient, and accurate, and they are used in a wide range of industries, including food and beverage, pharmaceuticals, and consumer products.

There are several benefits to use automated packaging systems, including:

- Increased speed and efficiency: Automated packaging systems can operate at much faster speeds than manual packaging processes, allowing for higher production volumes and shorter lead times.

- Improved accuracy: Automated packaging systems can accurately and consistently apply labels, fill containers, and seal packages, reducing the risk of errors or defects.

- Reduced labor costs: Automated packaging systems can significantly reduce the need for manual labor, leading to cost savings for businesses.

- Increased safety: Automated packaging systems can help to reduce the risk of accidents or injuries in the workplace, as they do not require workers to handle heavy or hazardous materials.

There are many different types of automated packaging systems, including filling and sealing machines, labeling machines, and packaging robots. The specific type of system used depends on the nature of the product being packaged and the requirements of the packaging process. Specific solution can be developped if standard equipment doesn’t meet the requirements.