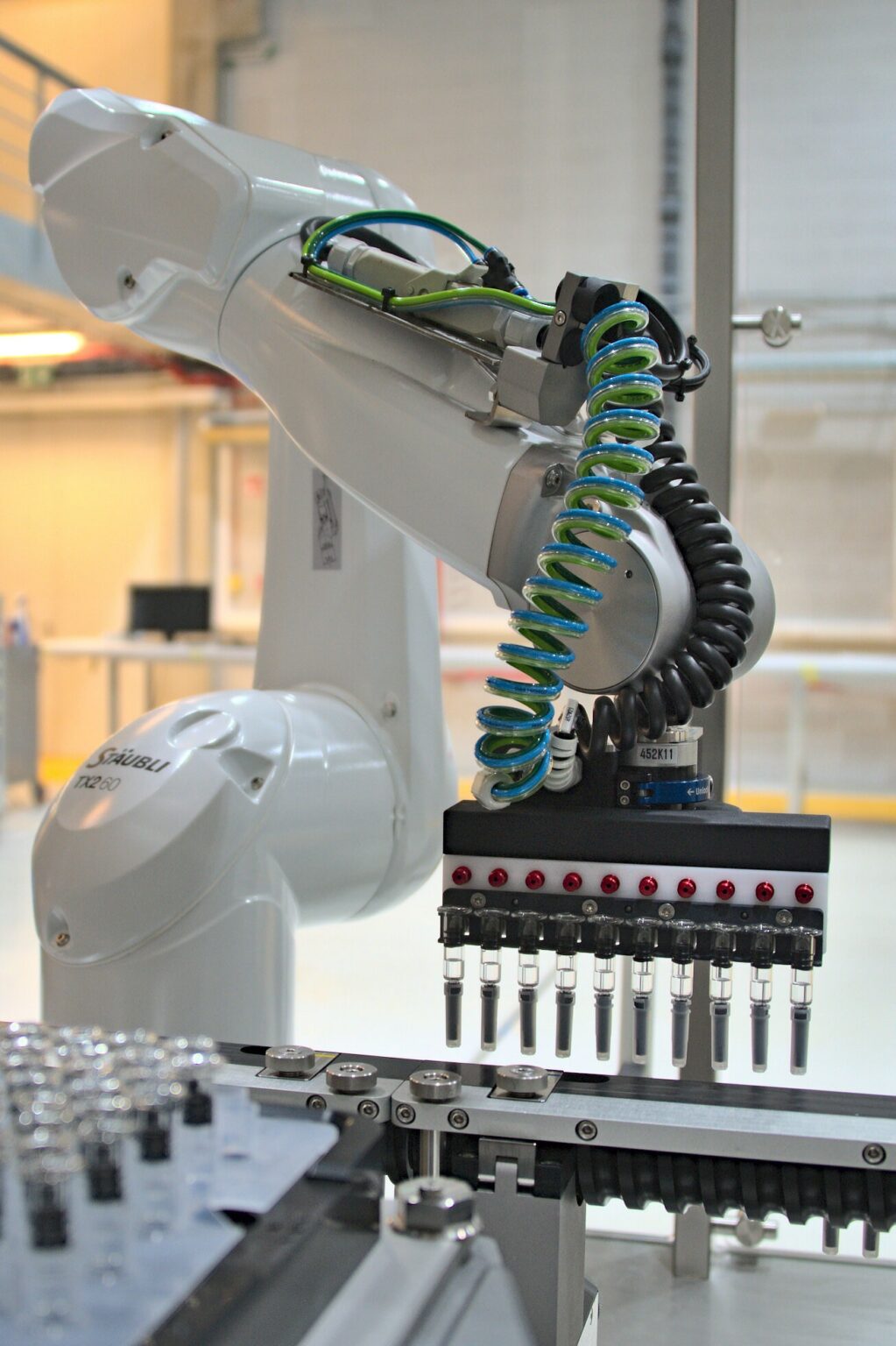

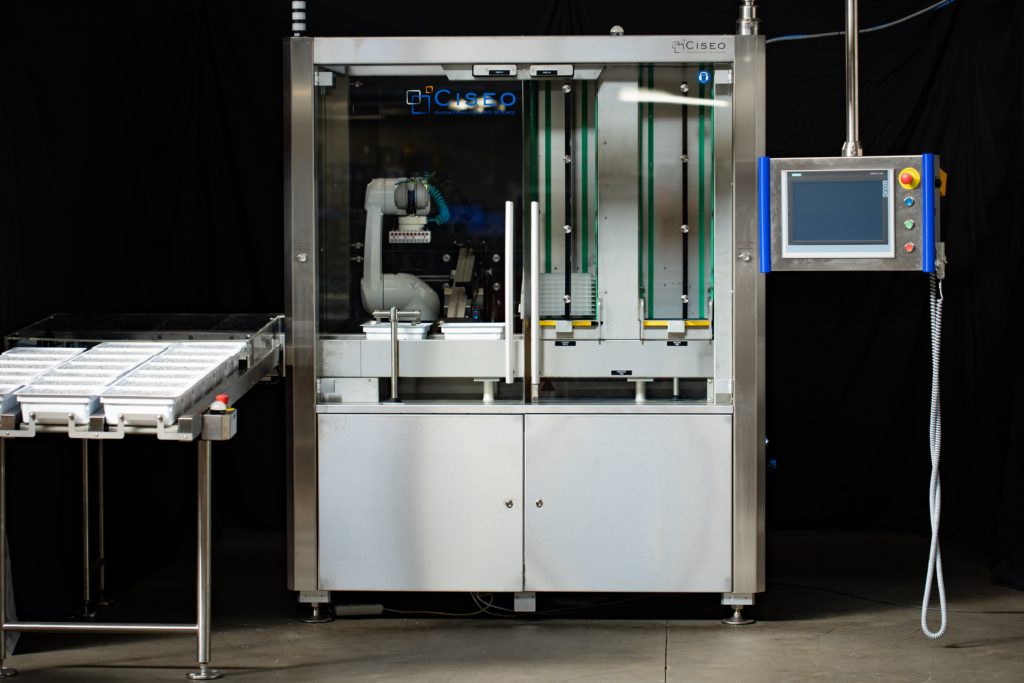

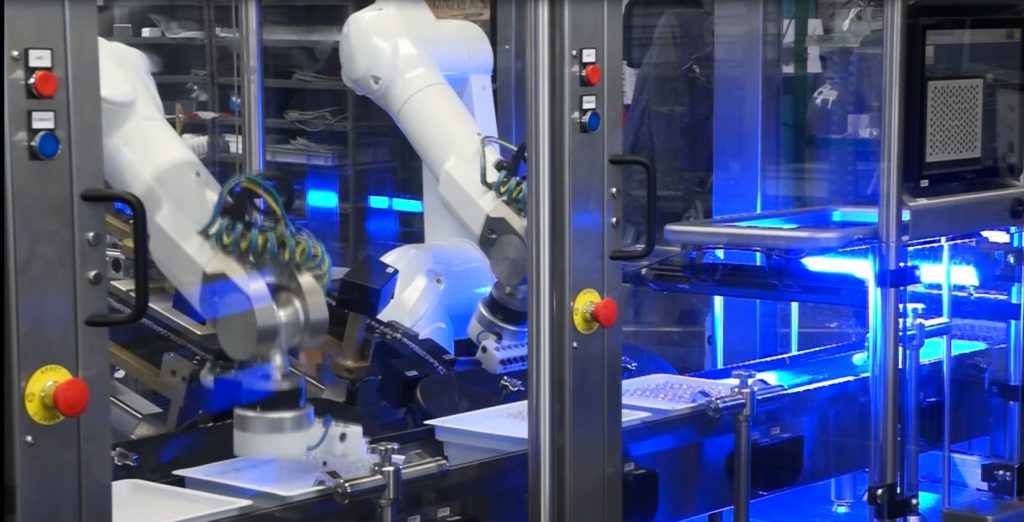

Performance and Reliability Pre-filled syringe nesting and denesting machines ensure precise and reliable packaging in nests, guaranteeing performance, safety, and cost-effectiveness. With their unique gripper and optimized robot trajectories, these machines perform handling operations while minimizing cycle time.

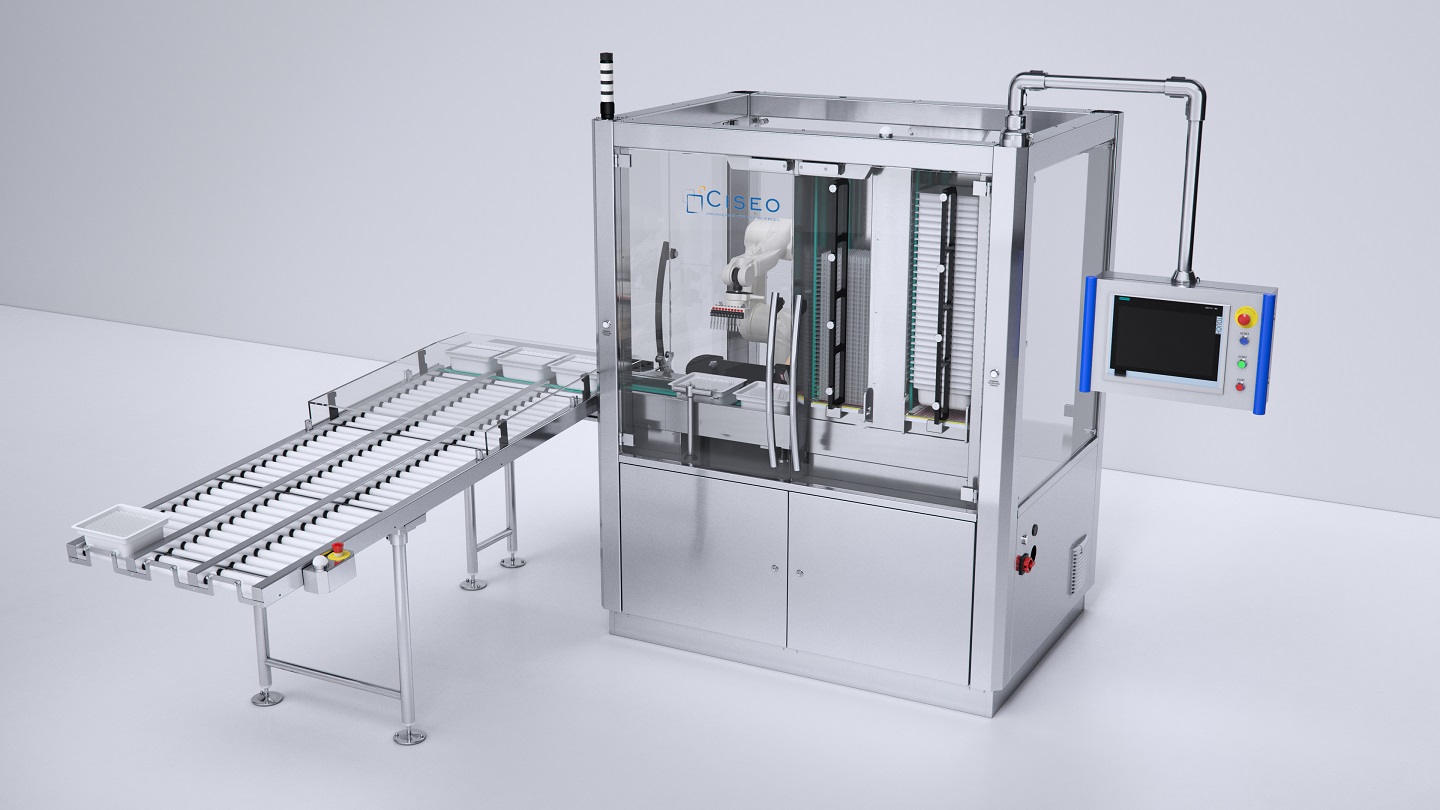

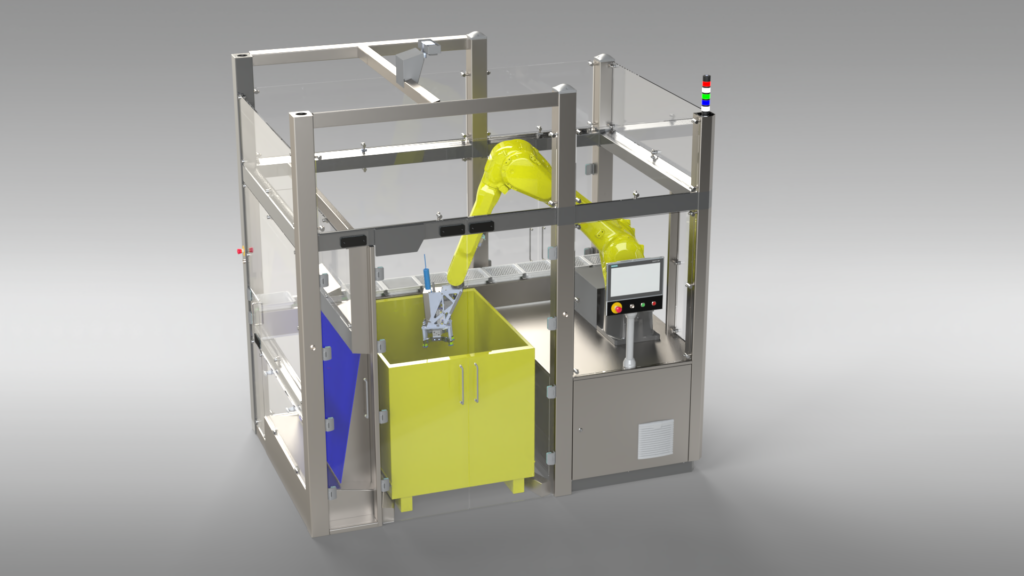

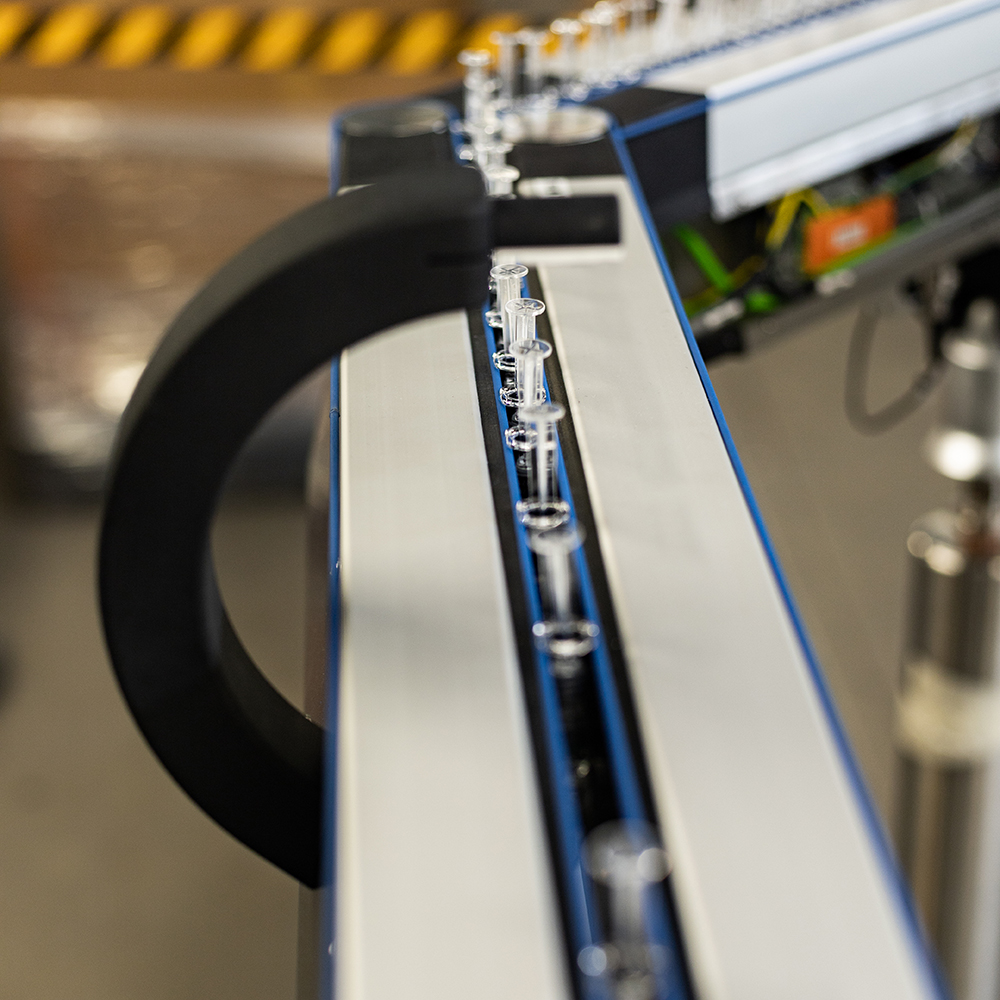

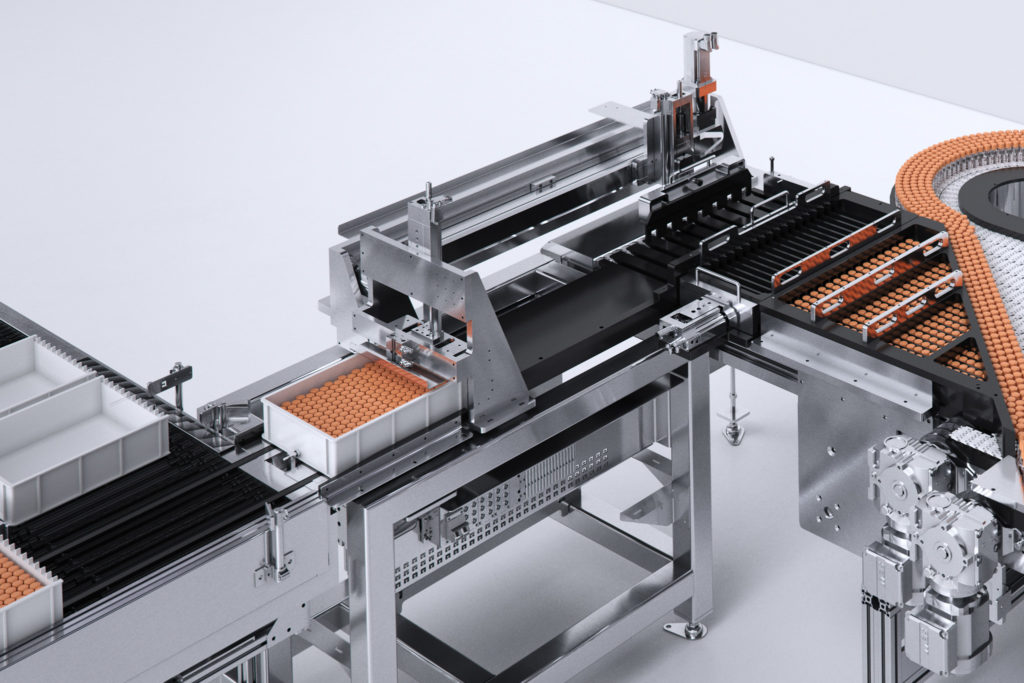

Automated Process Tubs are automatically conveyed to the nesting or denesting stations via a dedicated conveyor. The robot then retrieves the syringes and places them precisely onto a conveyor (denesting) or into the nest (nesting). Specific solutions ensure the absence of glass-to-glass or glass-to-metal contact between products. The achieved precision guarantees the integrity of the syringes throughout the process.

Multiple Speed Options The various solutions developed by CILYX allow operation at different speeds, from 150 cycles per minute to 1000 cycles per minute (9,000 to 60,000 syringes per hour). These machines offer exceptional productivity. The compact design of the nesting and denesting machines allows for easy integration into existing production lines.

Benefits The denesters and renesters meet the stringent requirements of the pharmaceutical industry in terms of reliability, robustness, and compactness. Their seamless integration into new or existing production lines increases productivity while ensuring operator safety.

Compliance and Certification CE-certified, these machines meet all the requirements of cGMP and GAMP5 good manufacturing practices, ensuring full compliance with industry quality and safety standards.