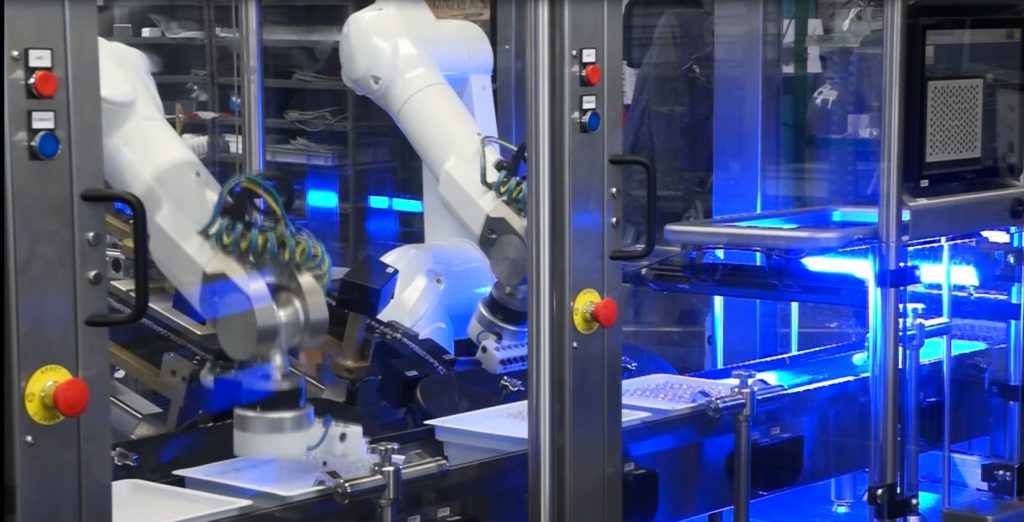

Performance and Reliability

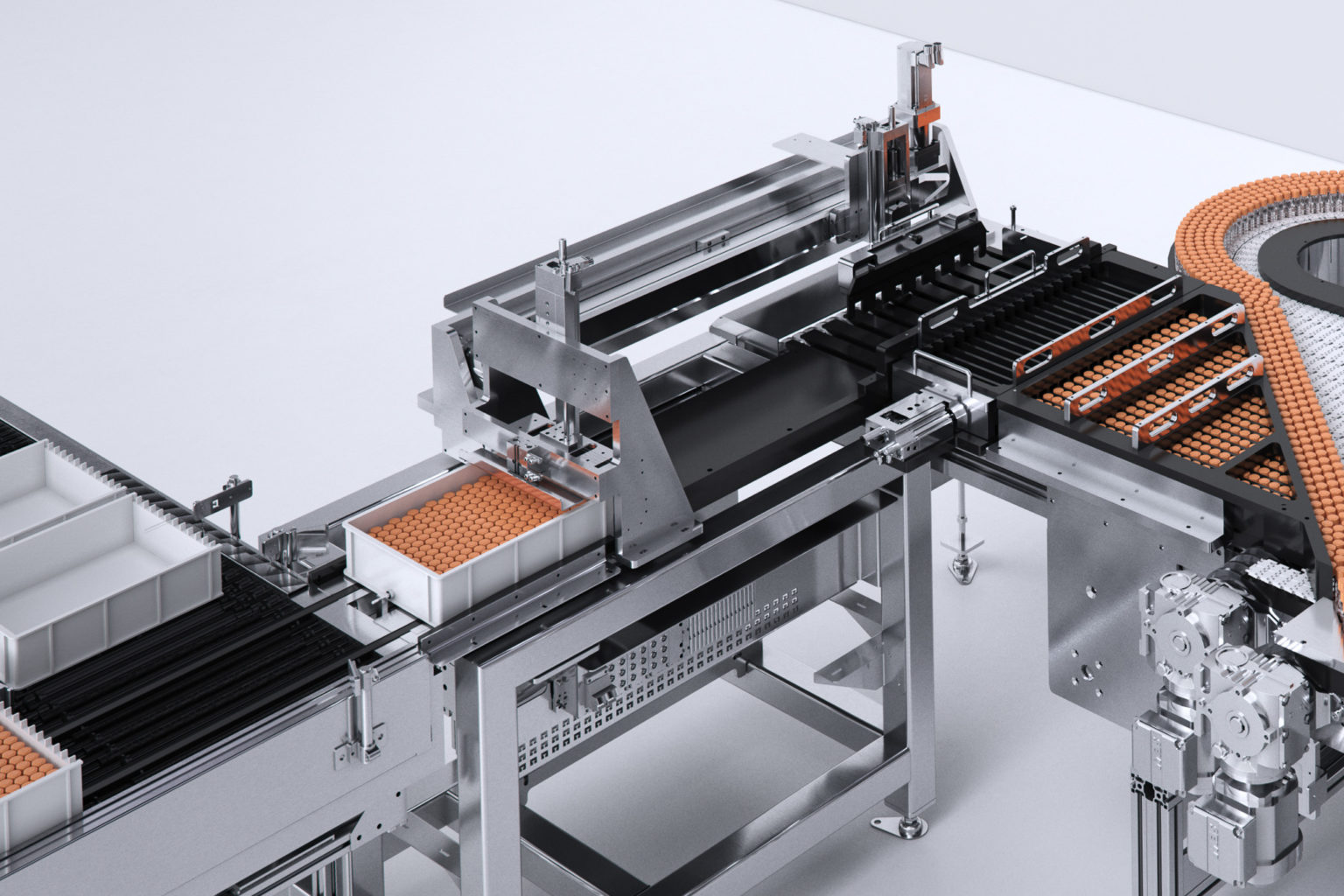

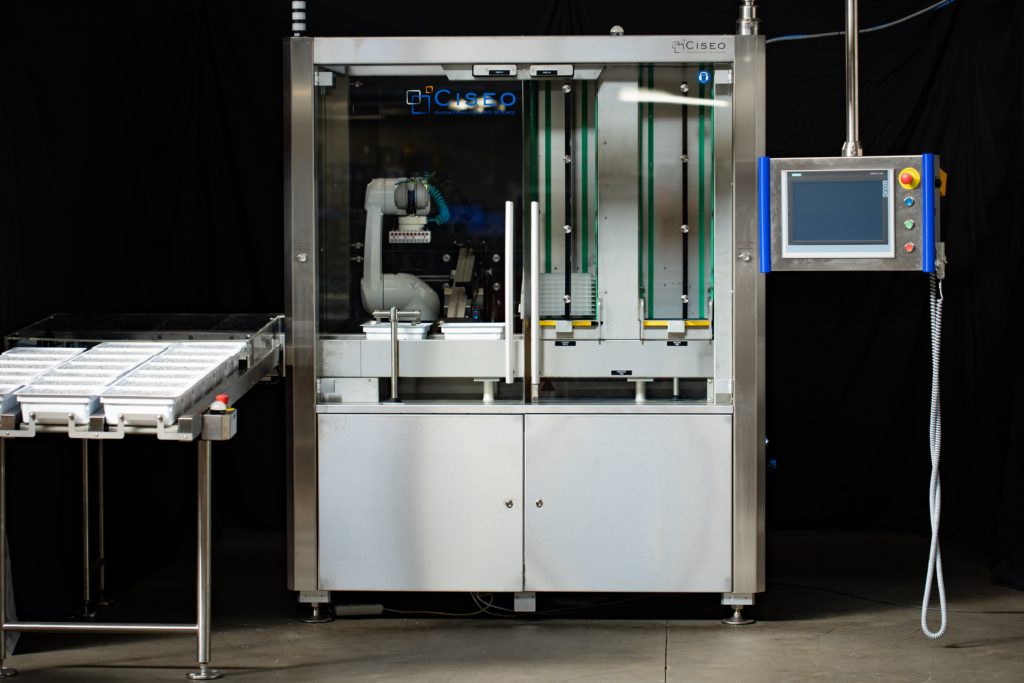

The vial handling machines for loading and unloading in trays ensure precise and reliable packaging, guaranteeing performance, safety, and cost-effectiveness. With their unique handling system, these machines perform operations while minimizing cycle time and maintaining product integrity. The vials are handled carefully to ensure they remain upright.

Staggered Placement

Often, vials are arranged in a staggered pattern within the trays, with a varying number of vials per line. These constraints are taken into account during both loading and unloading processes.

Akylux Trays

When trays are made of Akylux, their flexibility and slight dimensional variability make vial handling more complex. CILYX has developed solutions tailored to these production constraints.

Automated Process

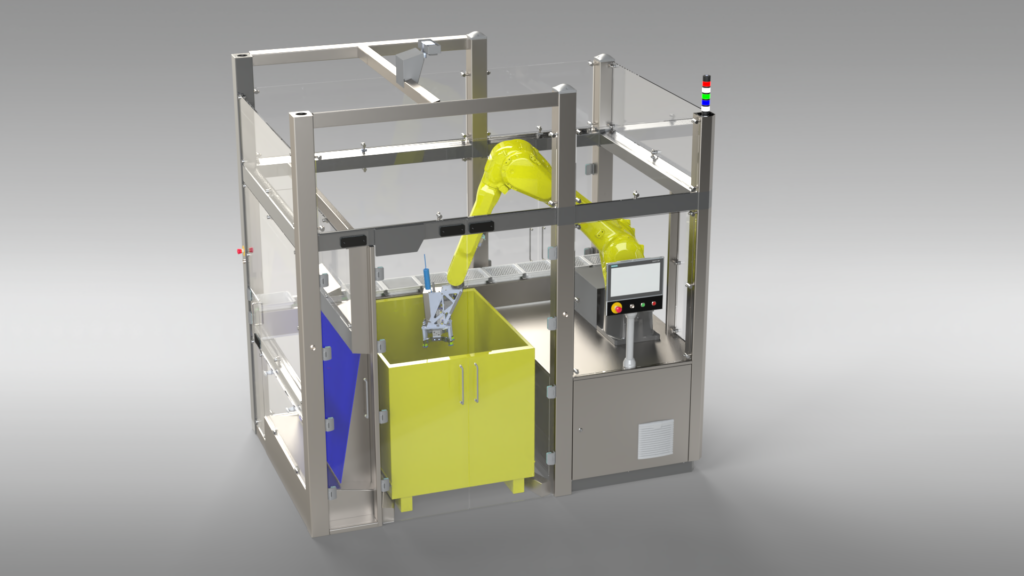

Trays are automatically conveyed to the loading or unloading stations via a dedicated conveyor. The handler then retrieves the vials and places them precisely onto a conveyor (for unloading) or into the tray (for loading). The achieved precision ensures the integrity of the vials throughout the process.

Multiple Speed Options

The various solutions developed by CILYX allow operation at different speeds, ranging from 100 cycles per minute to 600 cycles per minute (equivalent to 6,000 to 36,000 vials per hour). These machines offer exceptional productivity. The compact design of the handling machines allows for easy integration into existing production lines.

Benefits

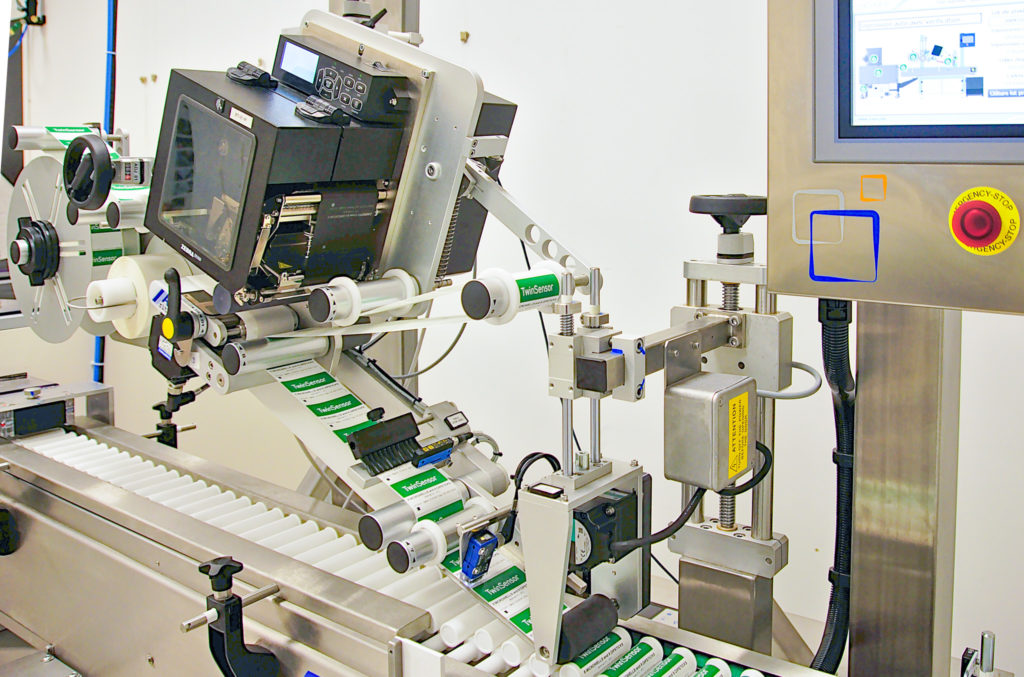

The loading and unloading machines meet the stringent requirements of the pharmaceutical industry in terms of reliability, robustness, and compactness. Their seamless integration into new or existing production lines increases productivity while ensuring operator safety.

Compliance and Certification

CE-certified, these machines meet all the requirements of cGMP and GAMP5 good manufacturing practices, ensuring full compliance with industry quality and safety standards.