Automation of Single-Use Systems

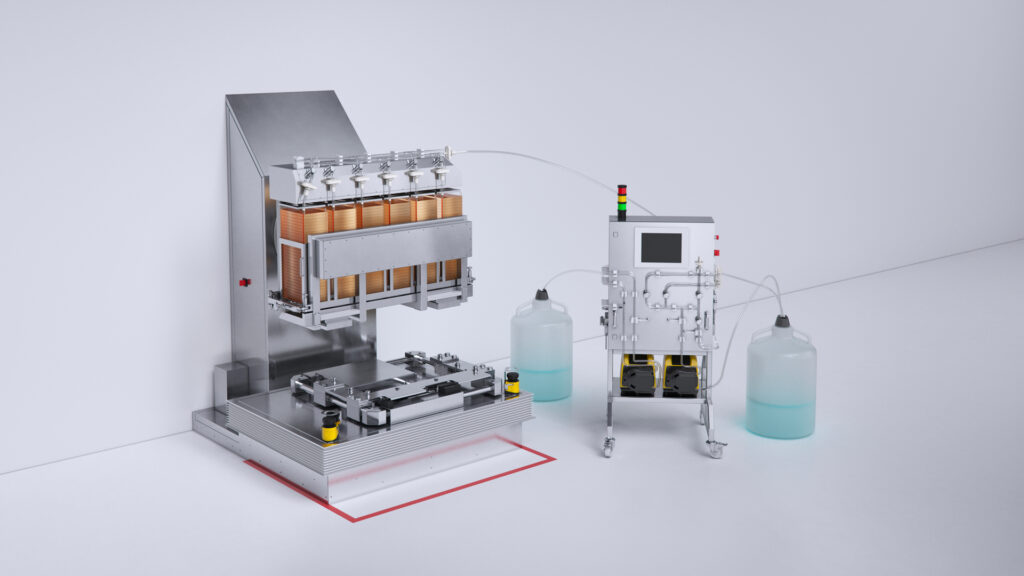

Sterilizing filtration of vaccines and parenteral drugs before filling is a crucial step in pharmaceutical good manufacturing practices. To ensure this step is carried out under the safest conditions, the automated final filtration system offers advanced features: filter integrity testing before and after production (PUPSIT – Pre-Use, Post-Sterilization Integrity Testing), sterility assurance, and data integrity.

Automated Filtration and Adaptability

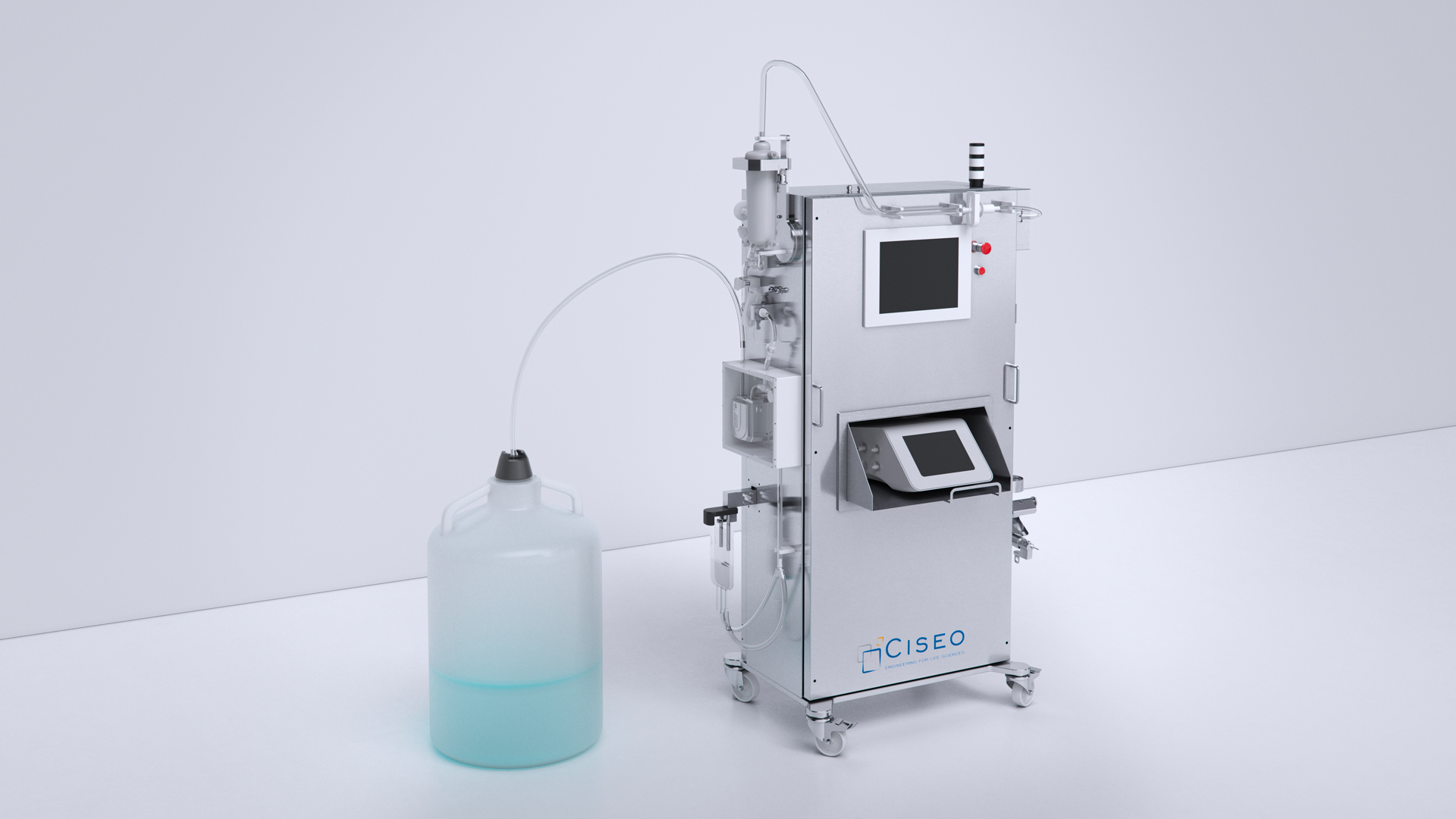

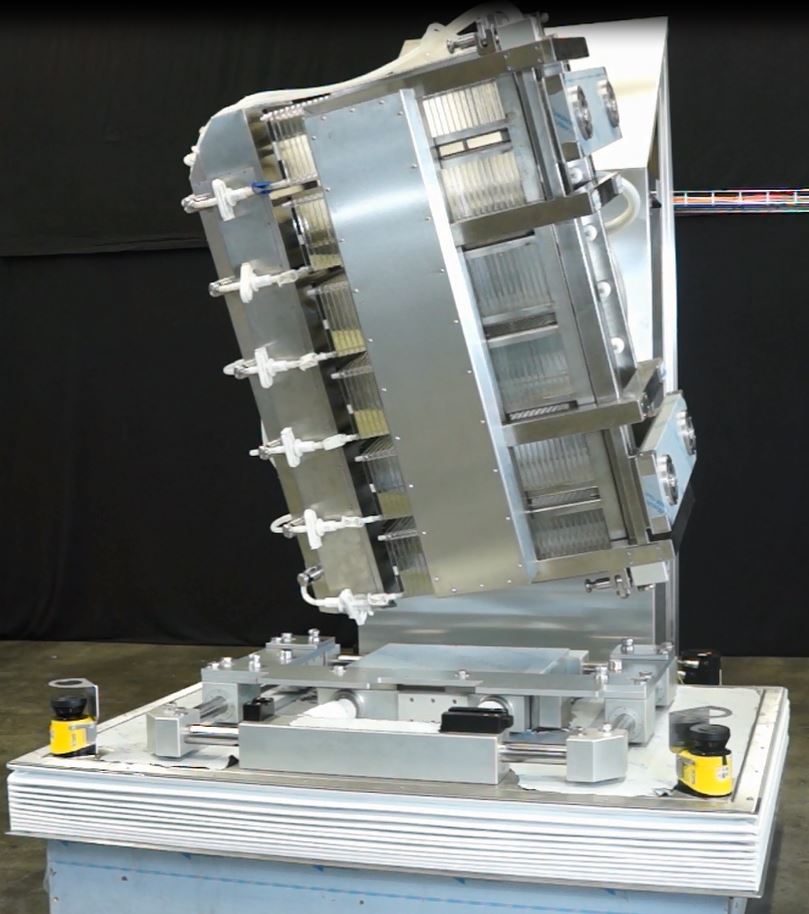

Our automated filtration system (AFS) simplifies the transfer and final filtration of your products by seamlessly integrating with your single-use systems, linking the finished product tank and the filler. Thanks to its high flexibility, the AFS is compatible with most common filter integrity testing equipment and a wide range of market sterilizing filters, such as Pall, Sartorius, and other brands.

Data Integrity and Reporting

The automated filtration system meets the rigorous requirements of the pharmaceutical industry: it ensures the transfer of production data (batch reports and audit trails) to the plant’s SCADA/MES system.

Compactness and Flexibility

The AFS is distinguished by its compactness, allowing smooth integration into often restricted production spaces. Its compact design optimizes space utilization while maintaining high operational efficiency. This compactness is paired with flexibility, facilitating the configuration of single-use assemblies to meet specific production needs.

Compliance and Certification

Certified CE, the AFS fully adheres to cGMP and GAMP5 good manufacturing practices, ensuring complete compliance with industry quality and safety standards.