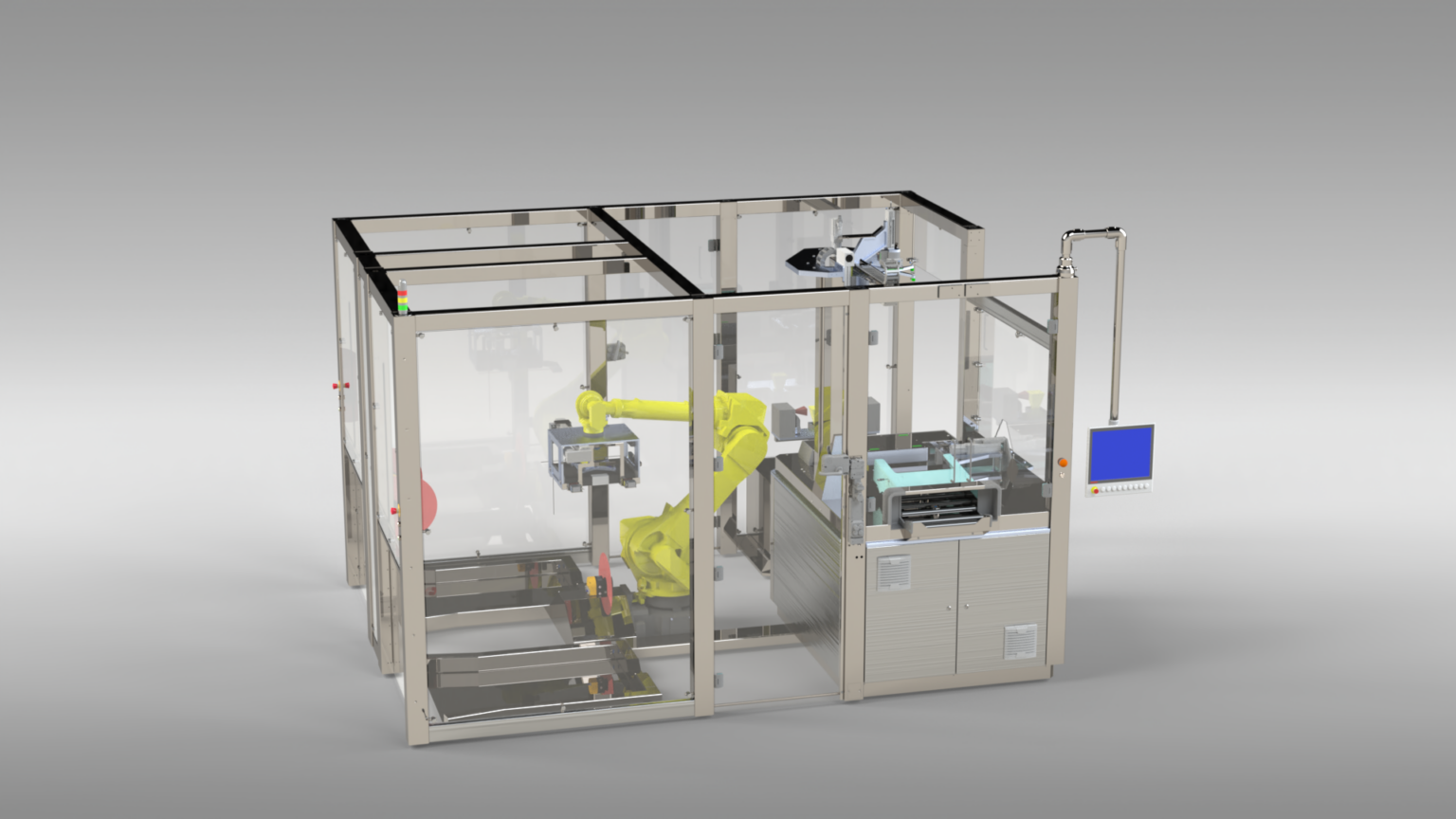

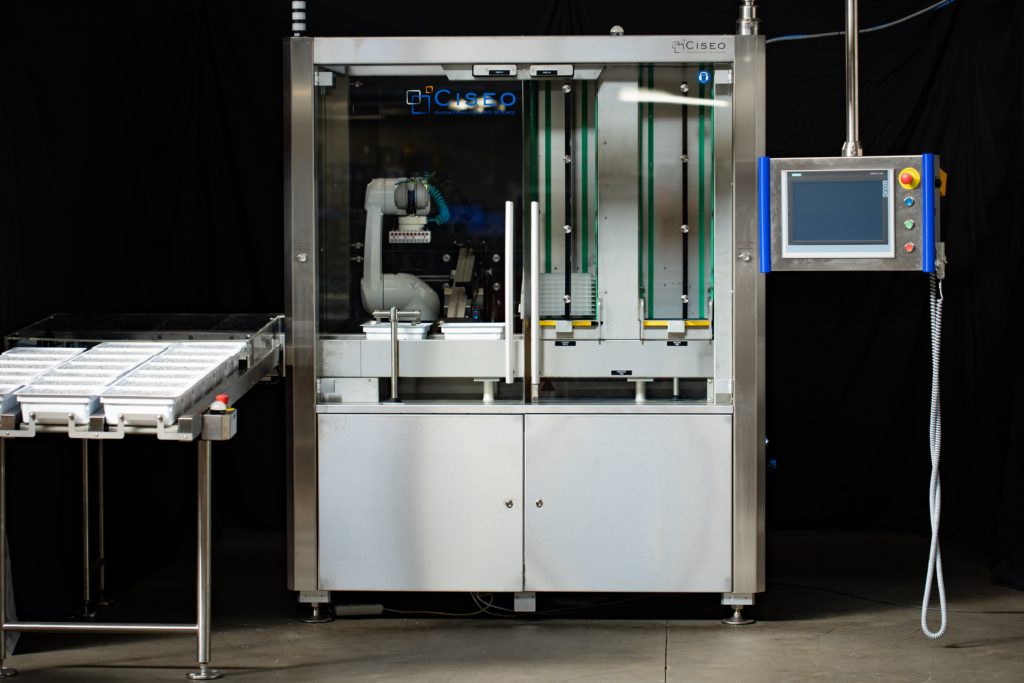

Automated Depalletization of Tubs and Akylux Trays

Depalletizing syringes in tubs or vials in trays, including Akylux trays which are more flexible and difficult to handle, stored on pallets, is the first step in a fully automated packaging, wrapping, or product inspection line. This process is crucial for ensuring an optimized production flow, providing performance, reliability, safety, and cost-effectiveness.

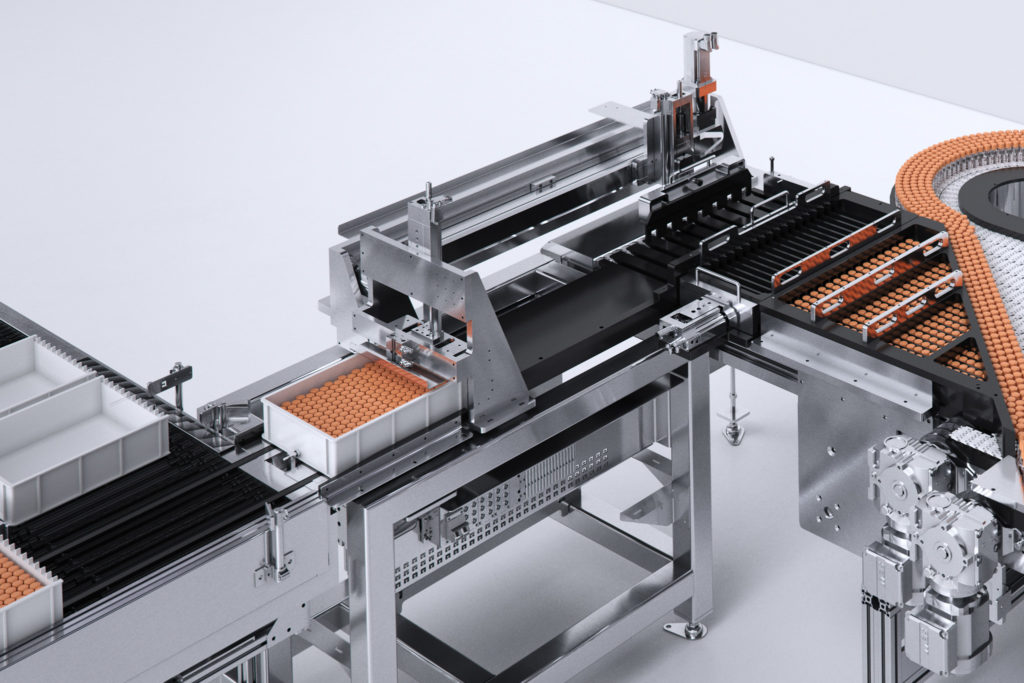

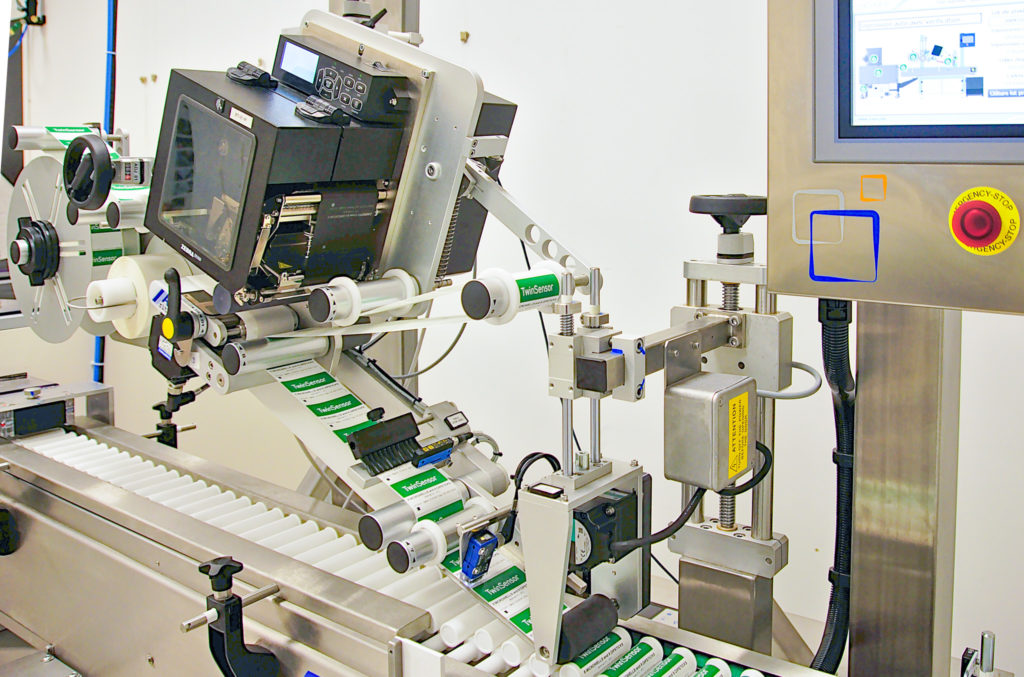

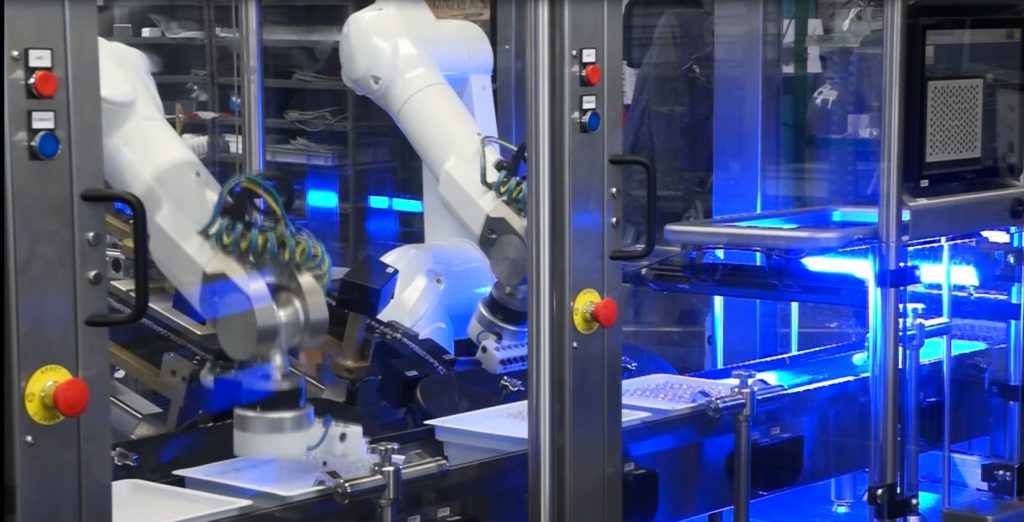

Intelligent Vision System

Depalletization requires an intelligent vision system to optimize the gripping sequence. This system identifies the most suitably positioned tubs or trays, allowing the robot to place them one by one onto a conveyor. The robot’s paths are carefully optimized to ensure product integrity.

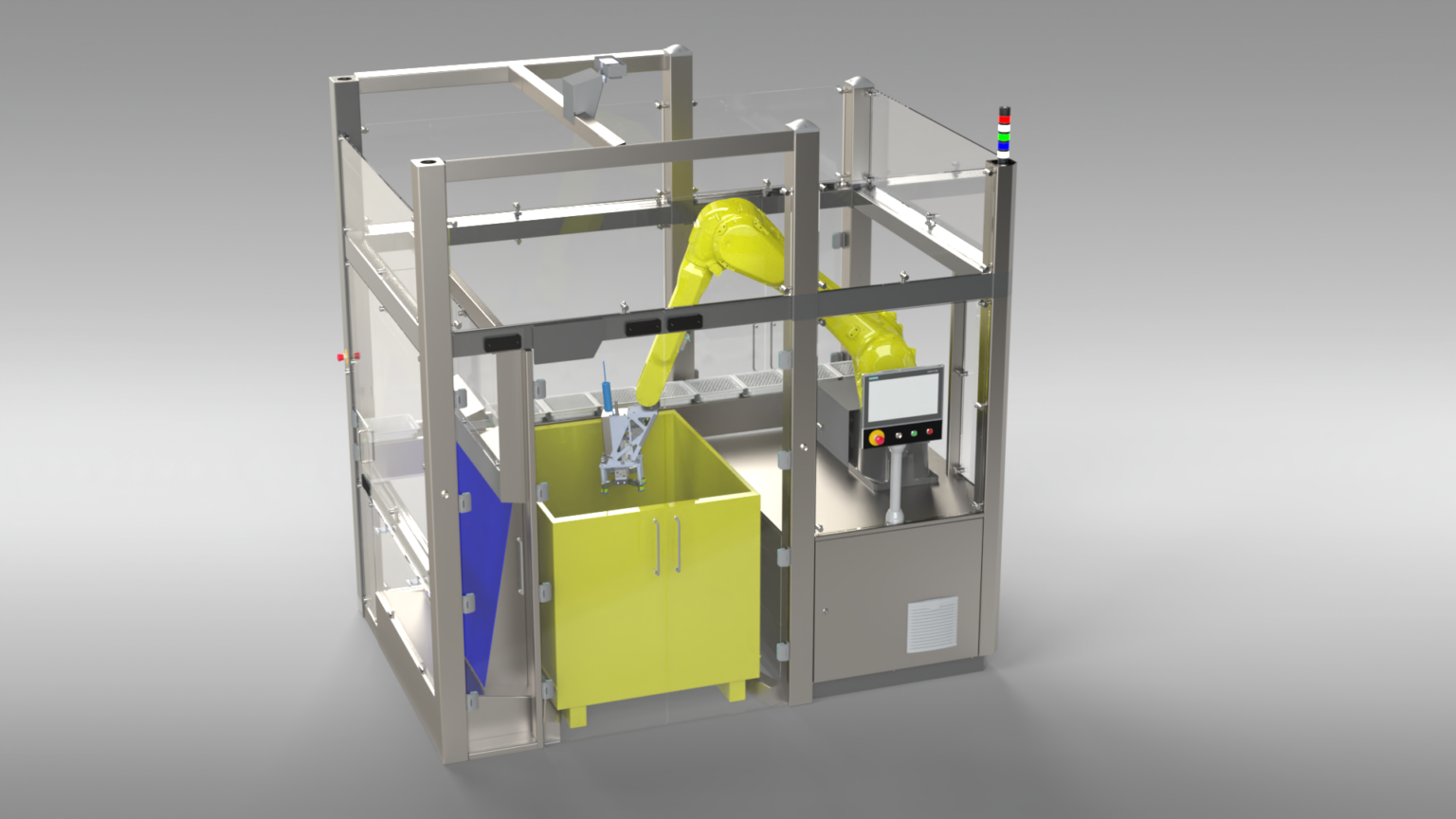

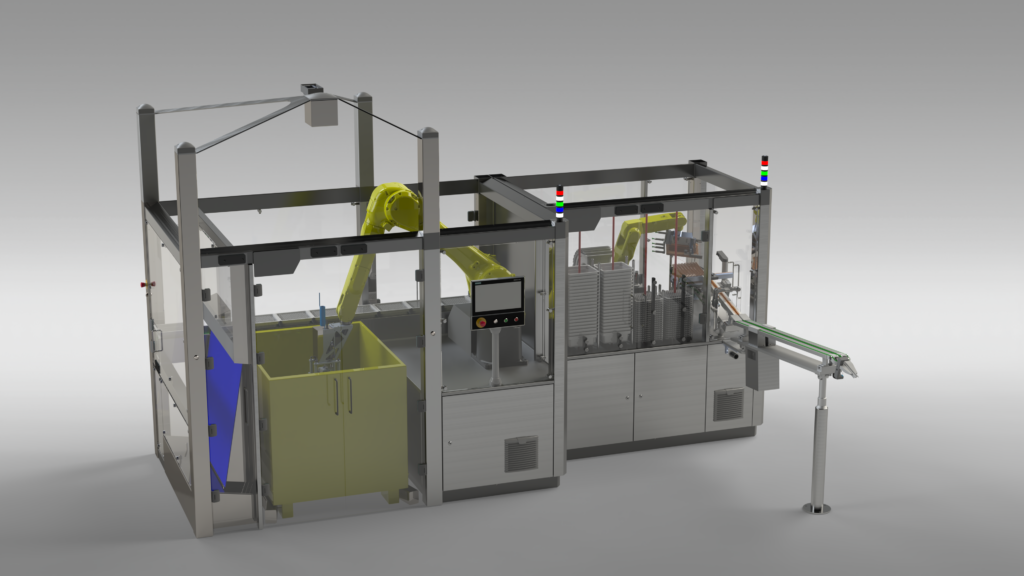

Palettization of Tubs and Akylux Trays

Palettizing tubs and trays at the end of the line is simpler than depalletization. It does not require an intelligent vision system. The system integrates a large-scale robot capable of reaching all positions on the pallet with tubs or trays. Often, two pallet positions are provided to avoid interrupting the robot during pallet changes. Integrated safety systems allow the operator to interact safely with the machine.

High Throughput

Our machines can achieve impressive speeds, from 600 to 1,000 syringes per minute, depending on the chosen configuration. This performance significantly increases the efficiency of your production line.

Choose our automated palettization and depalletization solutions to enhance productivity and safety in your packaging and wrapping operations.