In the pharmaceutical industry, the automation of bioprocesses has become essential to improving the efficiency and reproducibility of cell cultures and microorganisms. Our cutting-edge bioprocess automation solution offers optimized management of the upstream phase of bioproduction, ensuring reliable results and strict compliance with regulatory standards.

SOLUTION DESCRIPTION

The automation of bioproduction frequently requires the use of intermediate processes for the development of cell cultures or microorganisms. These cultures serve as the basis for the production of Active Pharmaceutical Ingredients (APIs), such as viruses, monoclonal antibodies, exosomes, or other complex biological products.

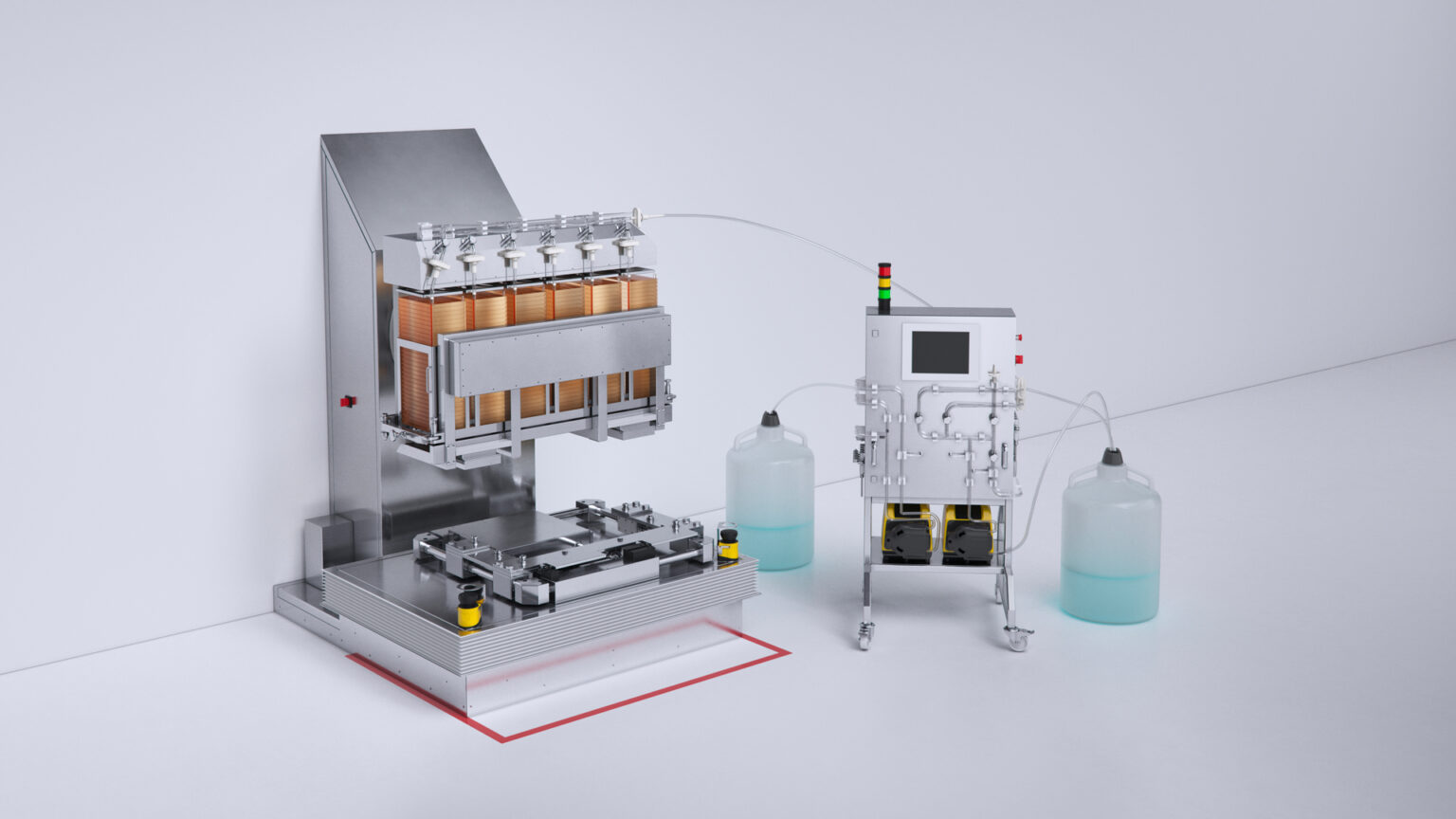

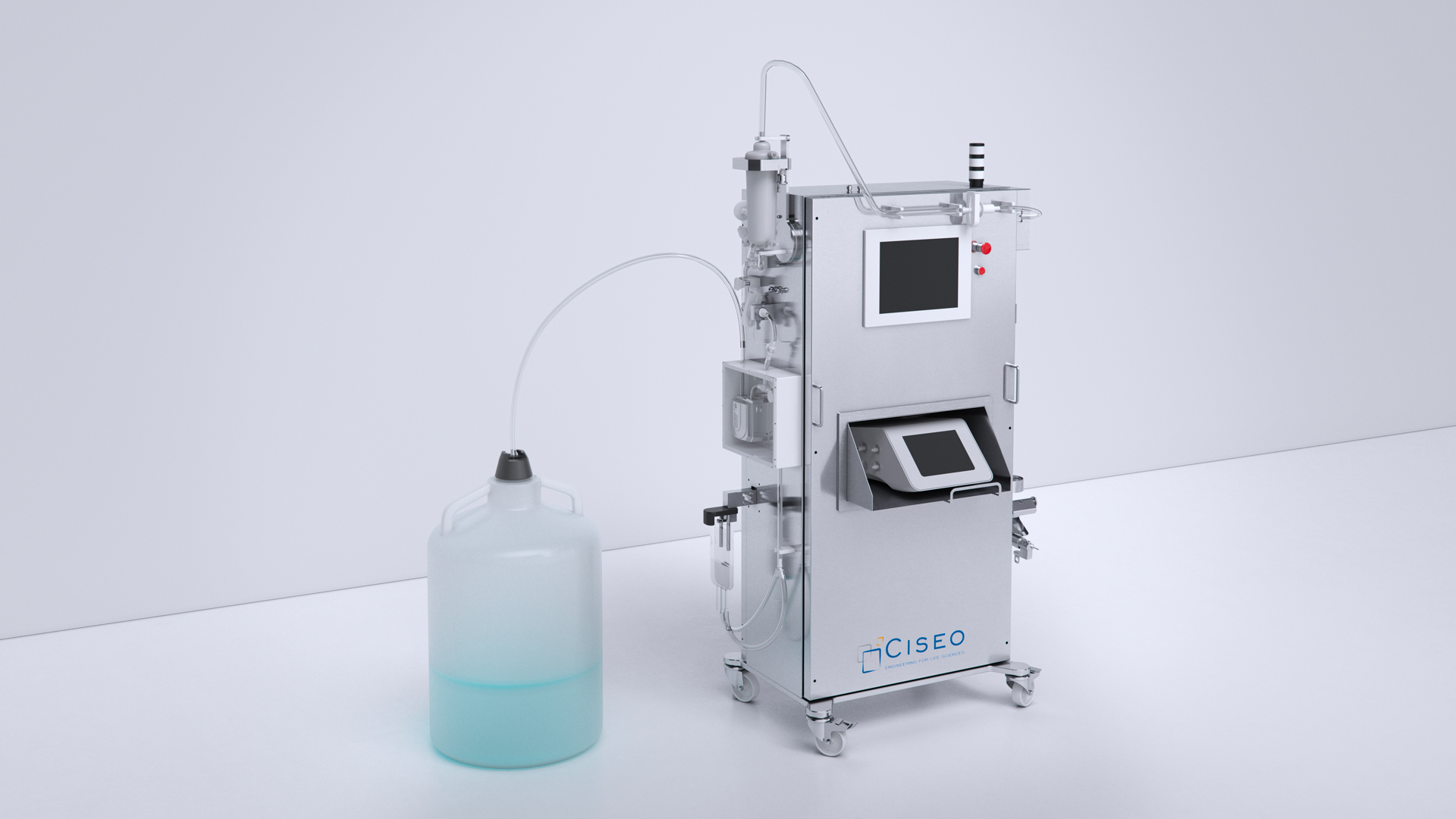

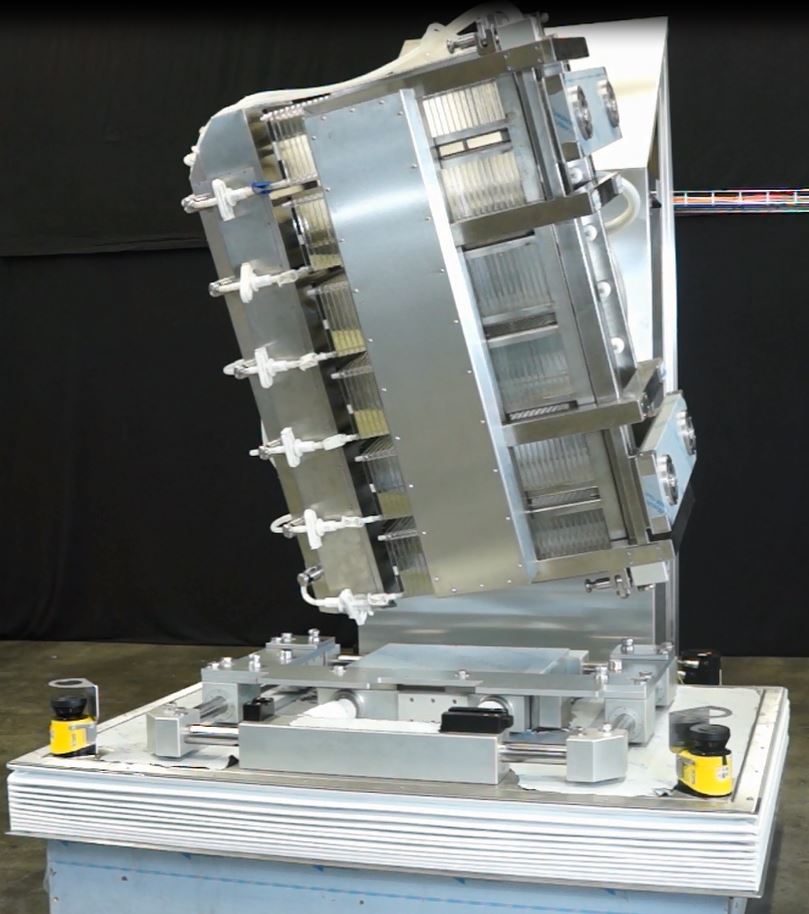

CILYX stands out for its expertise in bioprocess automation, particularly in the upstream phase of bioproduction using Single Use Systems, such as bioreactors and multi-layered cell culture platforms (like Cell Factory™ or Cell Stacks™).

Our solution enables precise and continuous monitoring of critical production parameters, including pH, temperature, dissolved oxygen concentration, agitation factors, and cell density.

Through this automation, cell culture processes become more homogeneous, thereby reducing inter-batch variations and significantly increasing production yields. Simultaneously, the automated generation of batch records and audit trails enhances production traceability, ensuring compliance with Good Manufacturing Practices (GMP) and facilitating internal and external audits.

CONCLUSION

Our bioprocess automation solution for the pharma and biotech sectors represents a significant advancement in the management of cell and microbial cultures. By choosing CILYX, you benefit from technology that not only improves the efficiency and quality of your production but also guarantees strict compliance with the highest industry standards.