Primary Packaging of Implants: Robotic Solutions for Precise Placement in Injectors

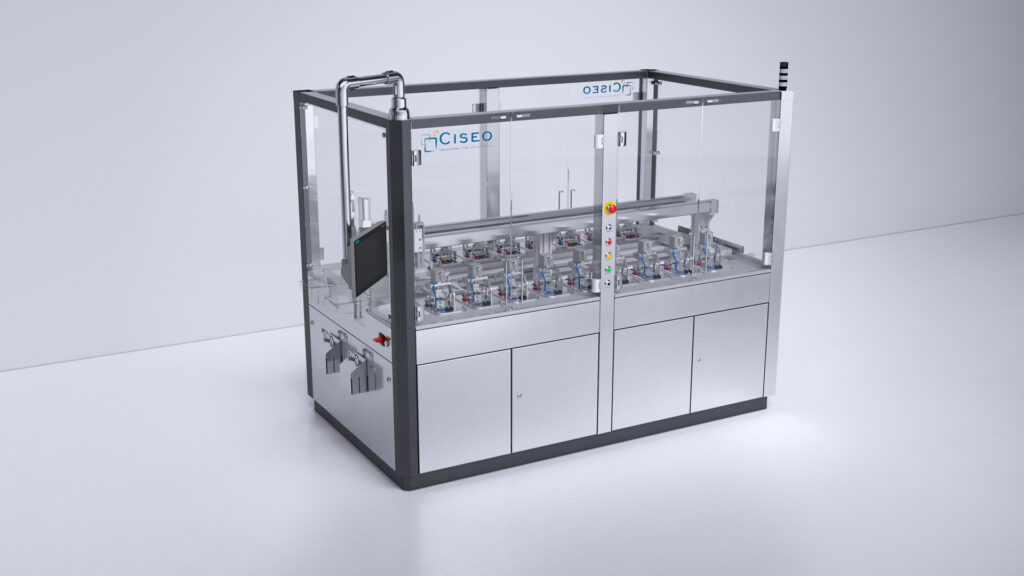

The primary packaging of pharmaceutical implants is of utmost importance, both for product protection and for ensuring their safety and efficacy during final use. In this context, the integration of robotic and automated solutions for the placement of implants in injectors represents a significant advancement, combining precision, efficiency, and reliability.

The Importance of Primary Packaging in Preserving Implants

Primary packaging is the first protective barrier for implants, playing a crucial role in maintaining their physical and chemical integrity. It shields the implants from contamination, mechanical damage, and environmental alterations. Moreover, effective packaging ensures that the implant remains sterile and ready for use, adhering to the strict standards of the pharmaceutical industry.

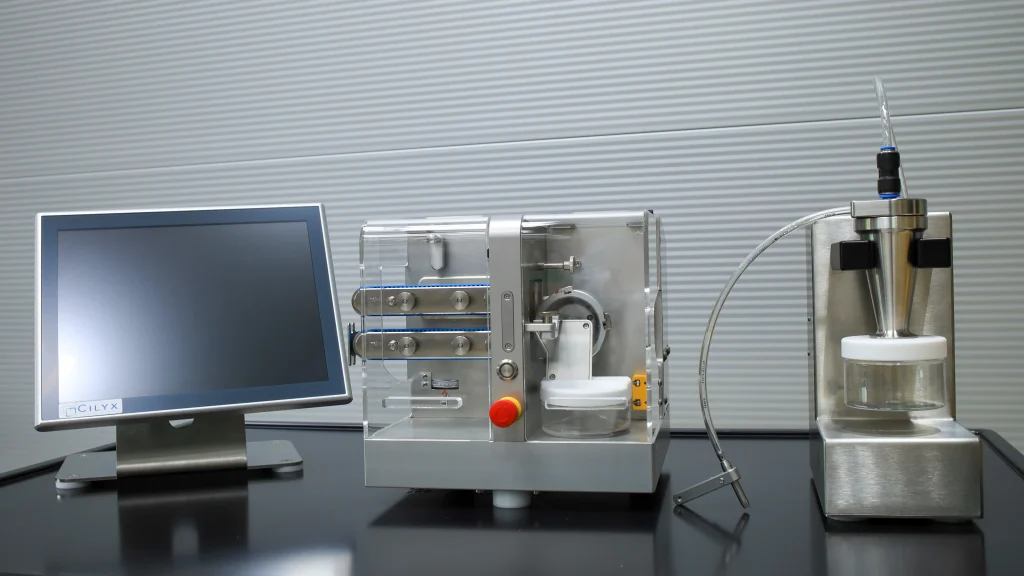

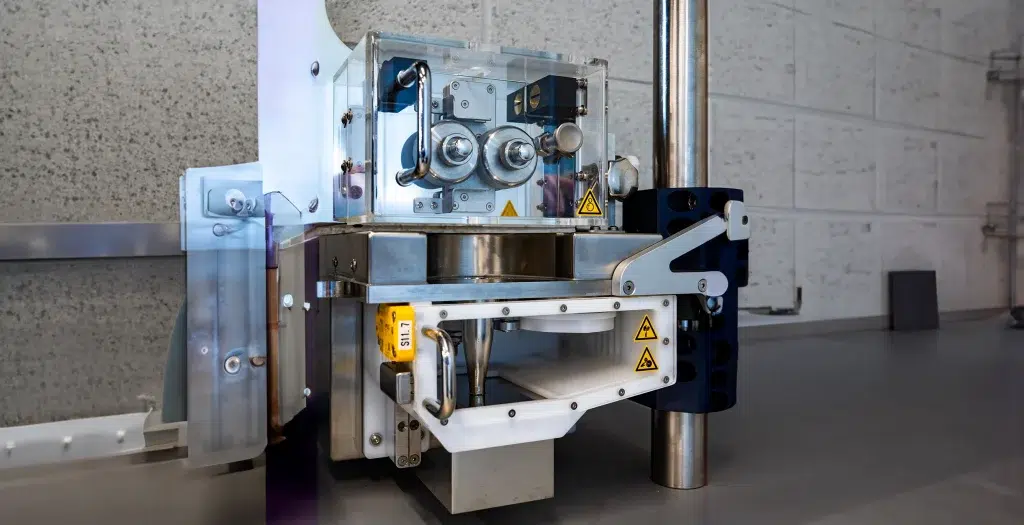

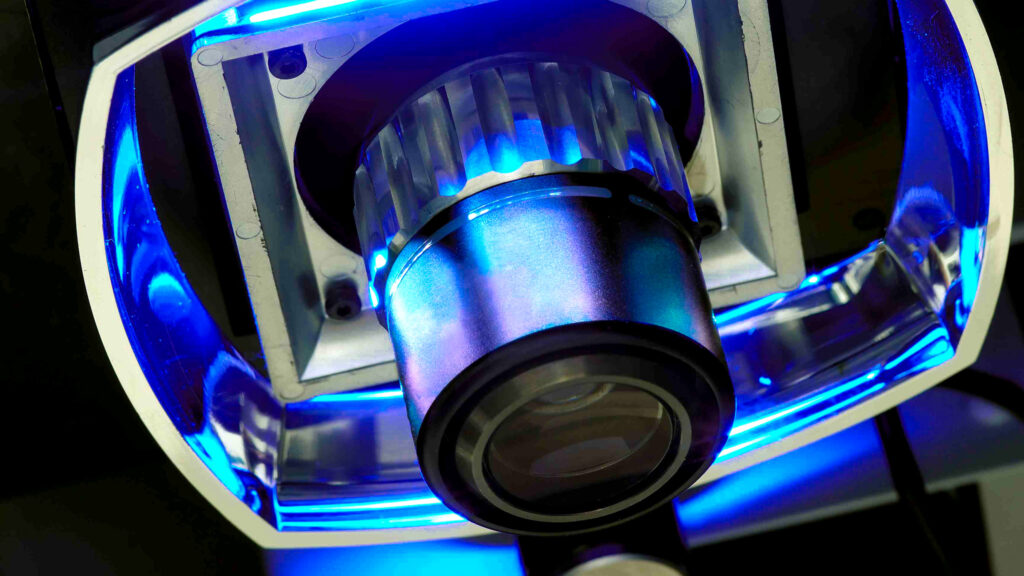

Automated Placement of Implants in Injectors: Precision and Safety

Thanks to advancements in robotics, the placement of implants in injectors can now be performed with unmatched precision. Robotic solutions are capable of handling implants with care, ensuring exact positioning within the injector. This automated process minimizes the risks of damage or contamination, ensuring that each implant is ready for safe and effective administration.