Denesting machine (DN400) No Glass to Glass for Life Sciences Industry

Denesting machine (DN400) No Glass to Glass for Life Sciences Industry

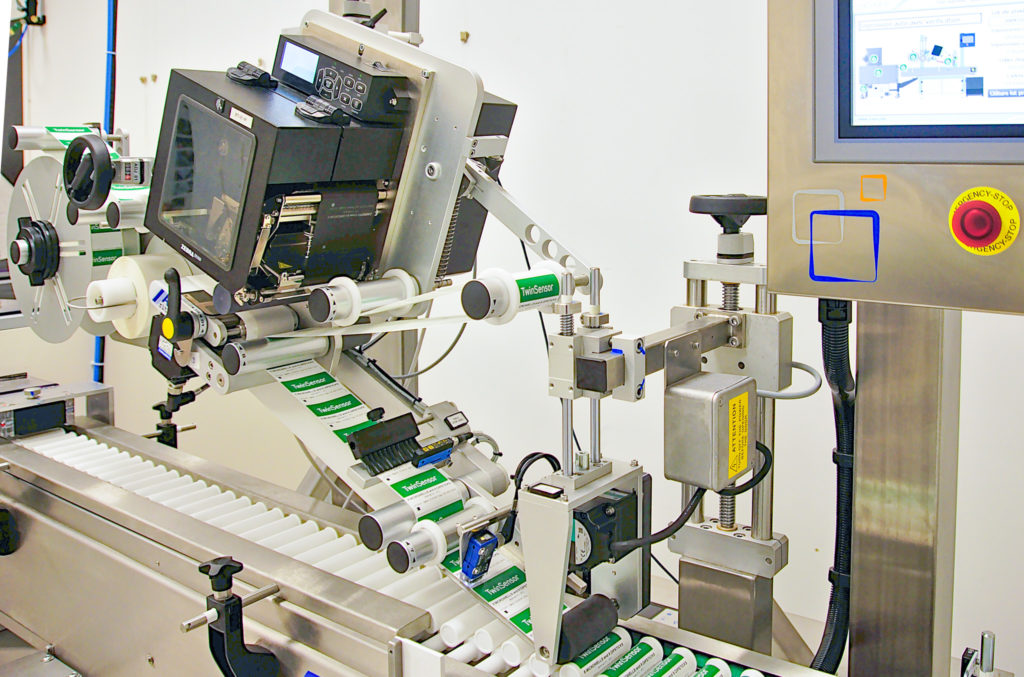

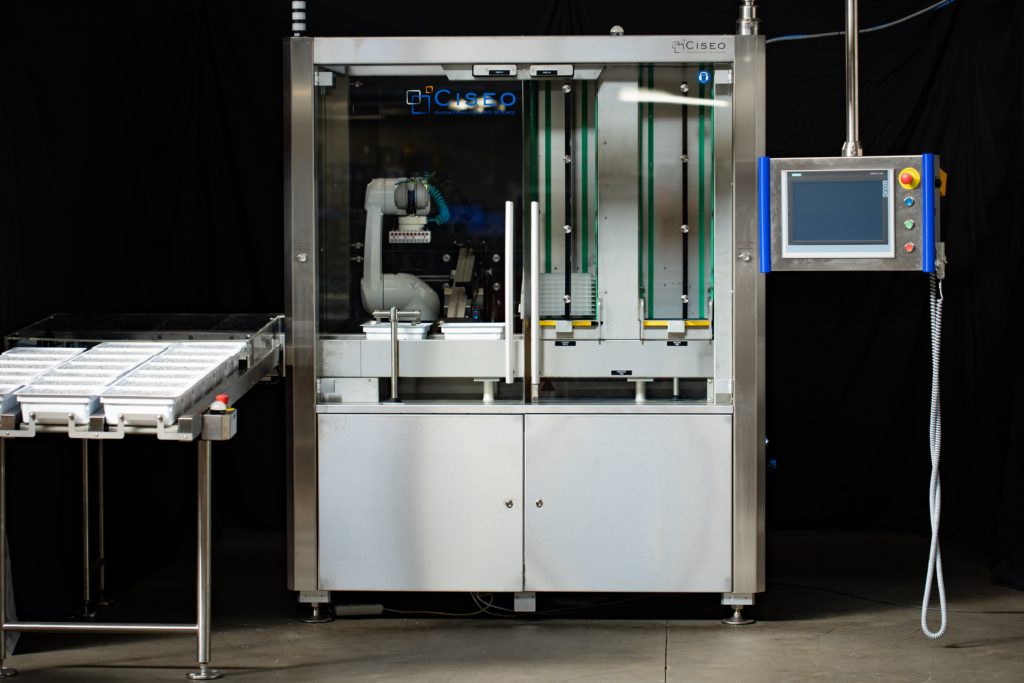

Designed by Cilyx to meet the needs of the pharmaceutical industry, the DN400 is robust, compact, and seamlessly integrates into your production line. With its advanced handling system, it ensures efficient and precise denesting of syringes, thus optimizing your productivity.

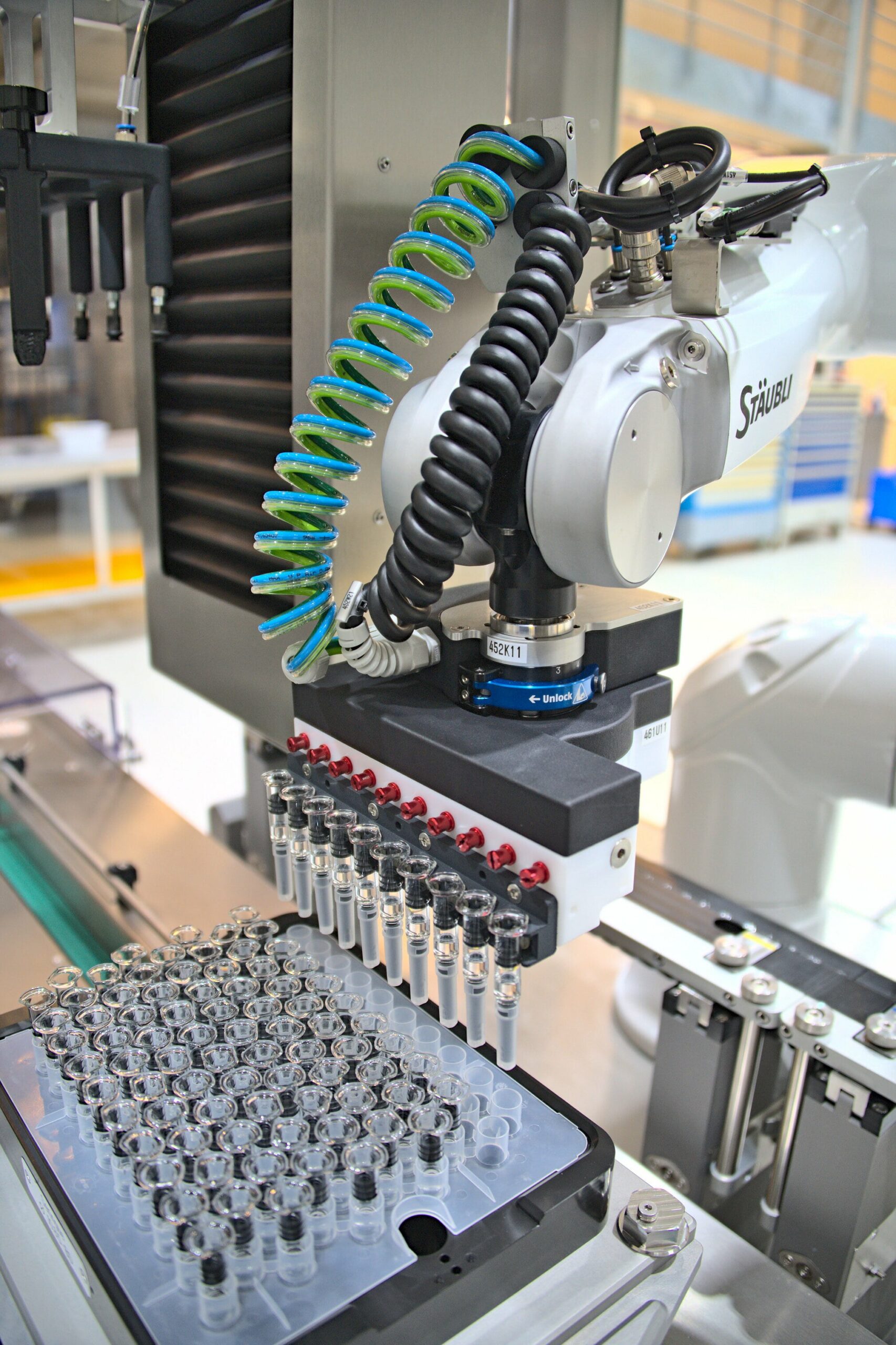

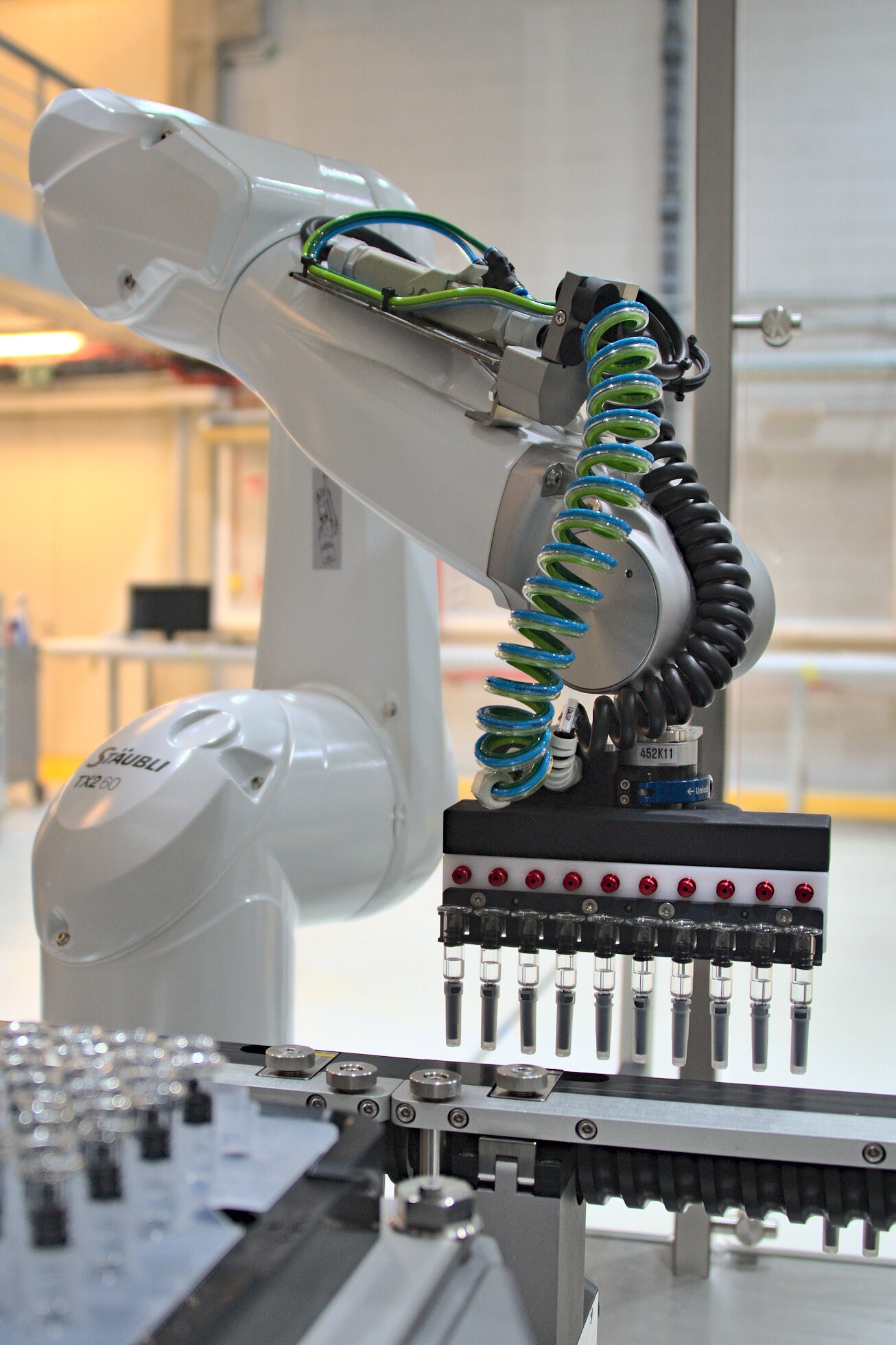

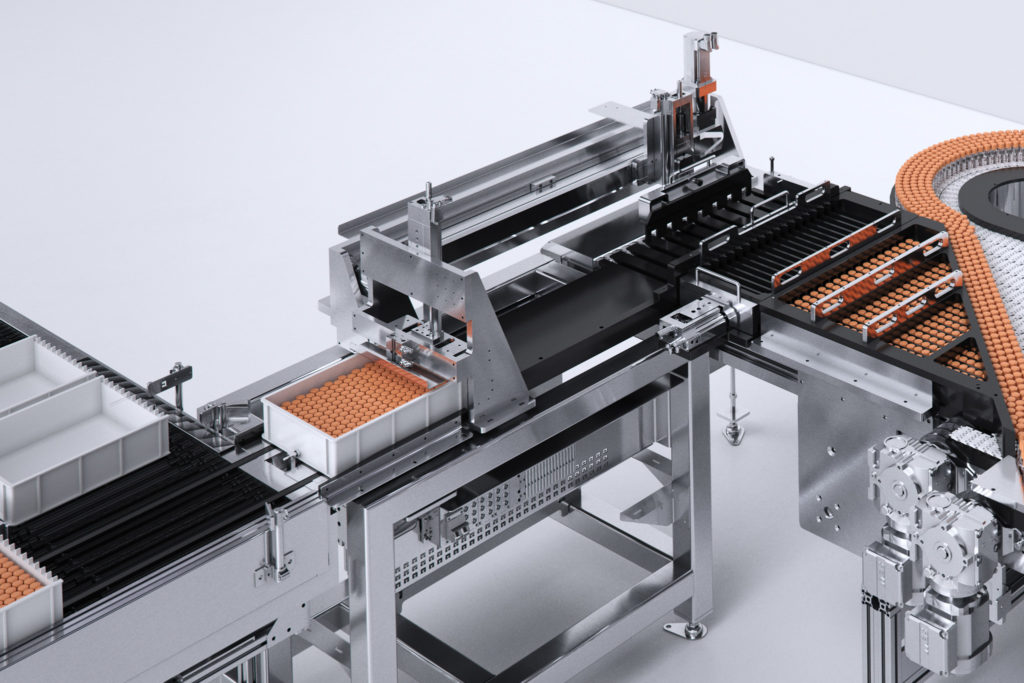

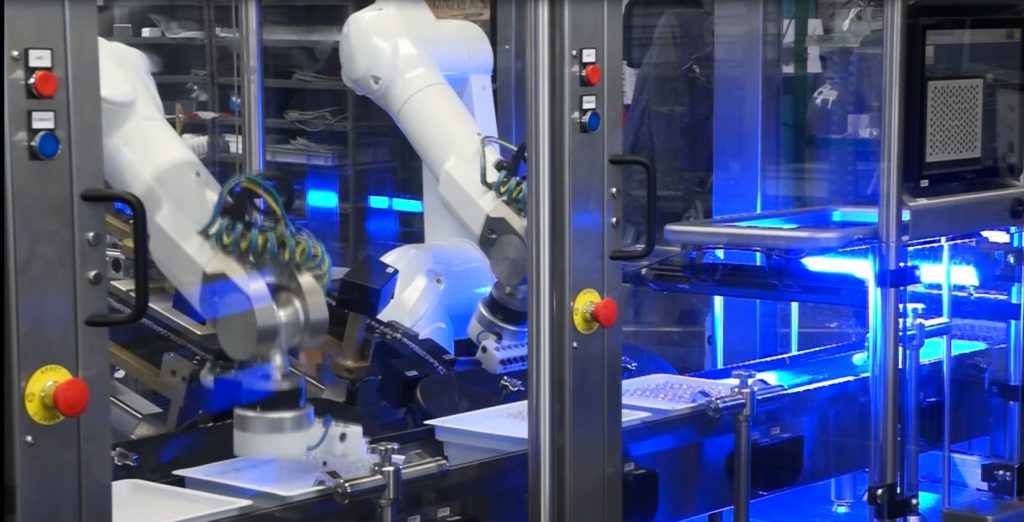

Start your process with up to 40 trays of pre-filled syringes, each containing up to 100 syringes, arranged on the conveyor. Once conveyed to the DN400, a robotic system handles the syringes in groups of 10 using suction cups. These syringes are then delicately placed on a spiral conveyor, ensuring smooth transfer to the next stage of the production line.

Featuring an impressive denesting capacity of 400 syringes per minute, or 24,000 syringes per hour, the machine ensures optimal performance while preserving operator safety.

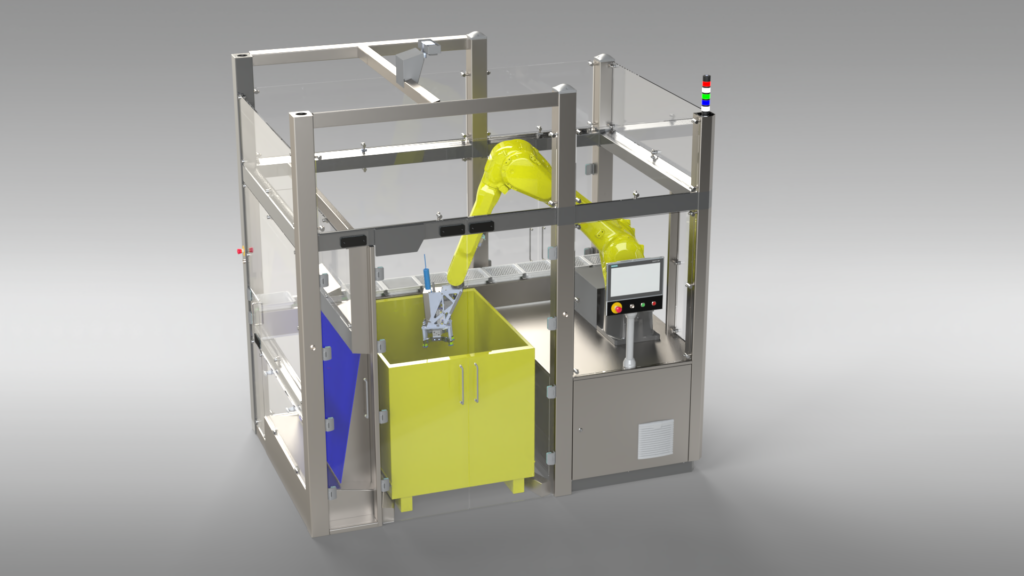

At the end of the process, the trays and nests are stacked in a vertical magazine, offering significant space savings and allowing the operator to focus on other tasks simultaneously. Furthermore, the compactness of the machine, combined with its cutting-edge design, incorporates a state-of-the-art robot. Thanks to a virtual enclosure, personnel safety is ensured while reducing physical equipment footprint. This technology allows for more efficient use of space while maintaining high safety standards.

Advantages

Here are the benefits of this machine:

- Perfectly meets the needs of pharmaceutical industries in terms of robustness, compactness, and seamless integration into your production line.

- Increases your company’s productivity while ensuring the safety of your operators.

- CE certified, compliant with all cGMP and GAMP5 good manufacturing practice requirements.

- With an initial design tailored to 10×85 diameter syringes, our automatic denesting machine offers great versatility. It can be easily adjusted to accommodate other diameters, ensuring optimal flexibility to meet your evolving needs.

- Delicately handles syringes to preserve their integrity, thus avoiding any risk of impact or damage (no glass to glass technology).

- Thanks to our mechanism allowing the robot to work continuously with two tray positions, you benefit from maximum efficiency without compromising quality.

- Our system integrates tray flipping at the end of the process to prevent fluid mixing and ensure complete tray emptying after denesting.

- Finally, our solution includes an integrated vertical magazine for tubs and nests, offering optimal use of space and seamless integration into your production environment.

Specifications

| Elements | Processing range |

|---|---|

| Robots | 6 axes Robot 6 axes foreseen for the life sciences industry |

| Speed | 400 syringes treated per minutes |