Depalletization & palletization

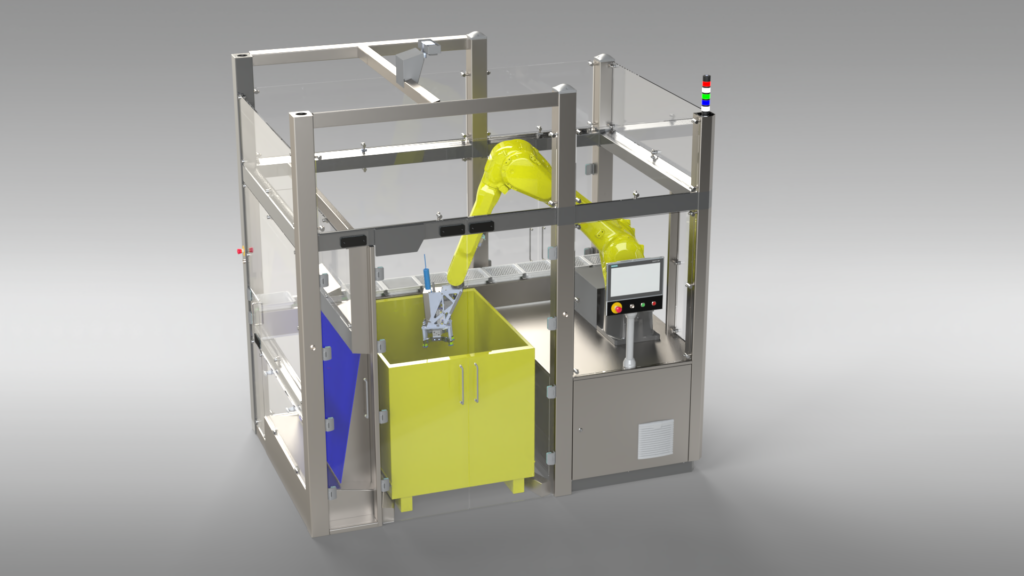

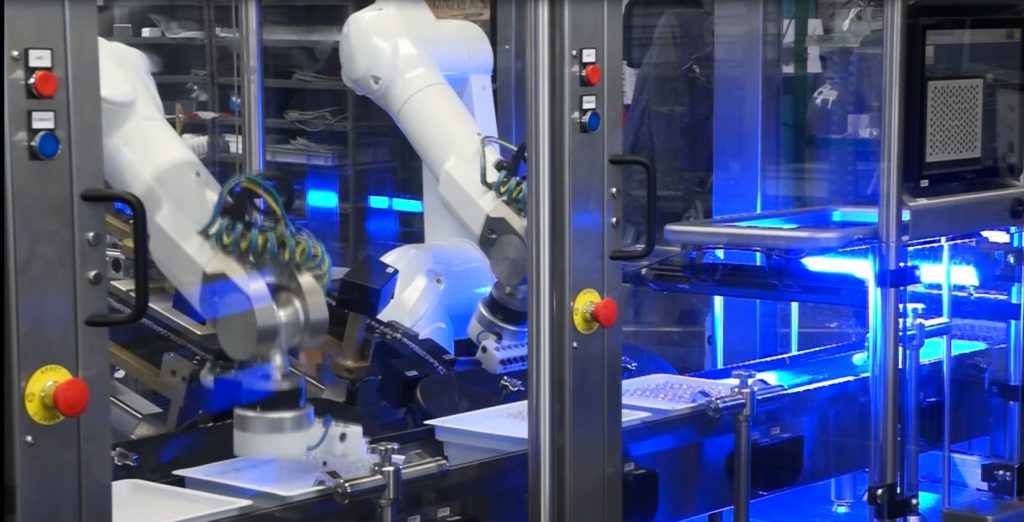

The repackaging of syringes in nests is an important step that must ensure performance, reliability, and safety. Cilyx offers the opportunity to automate this process with the RN150.

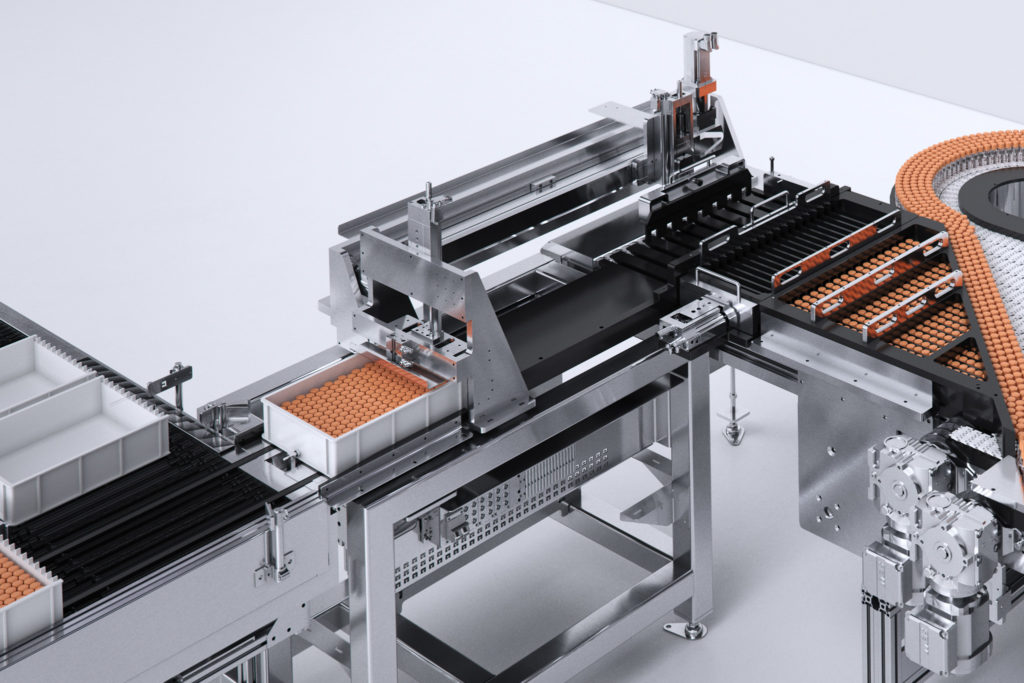

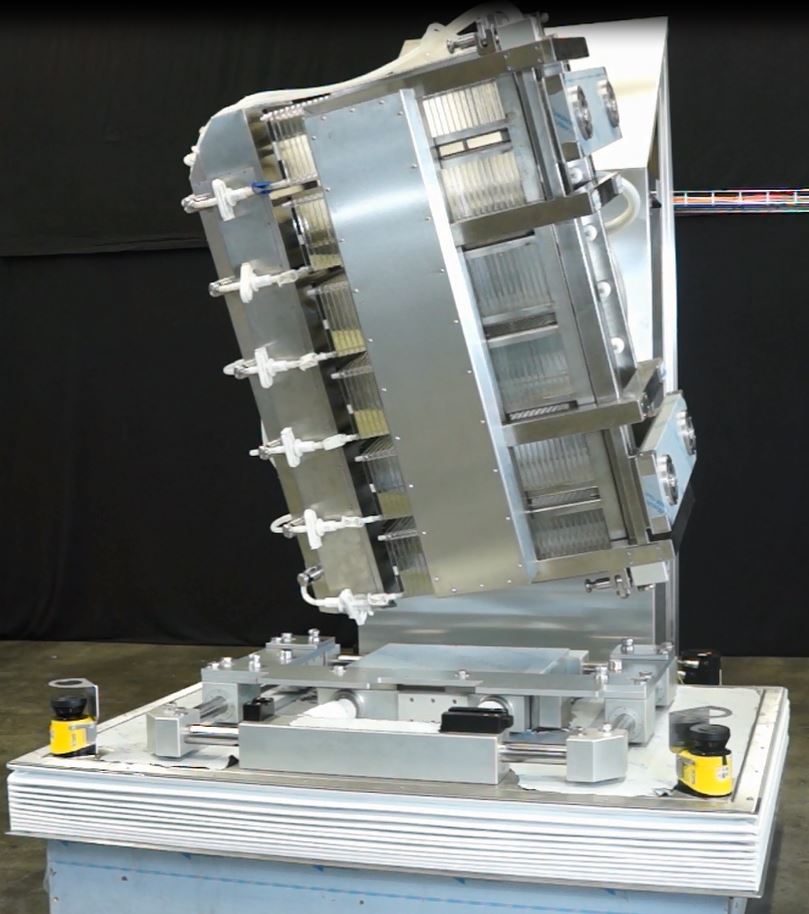

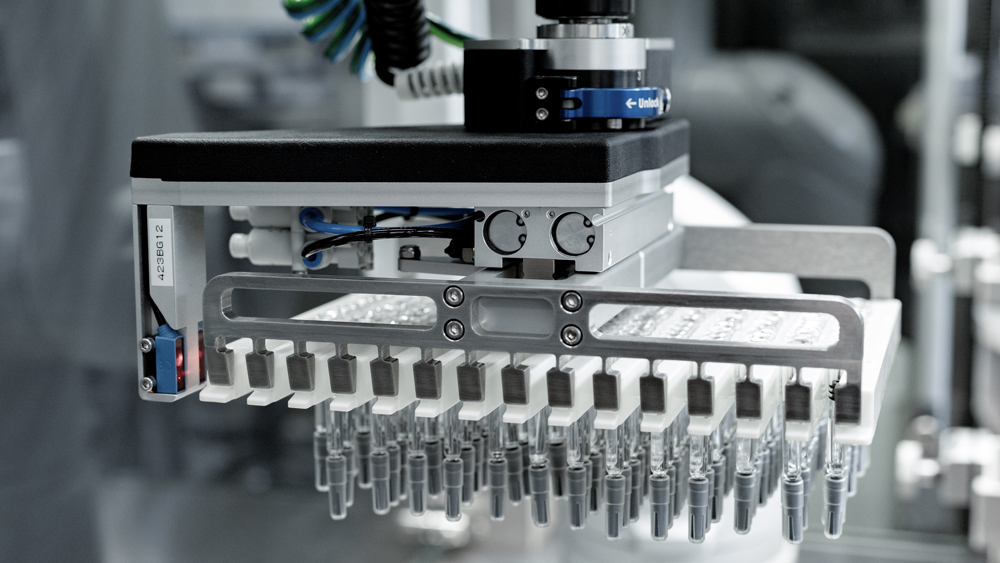

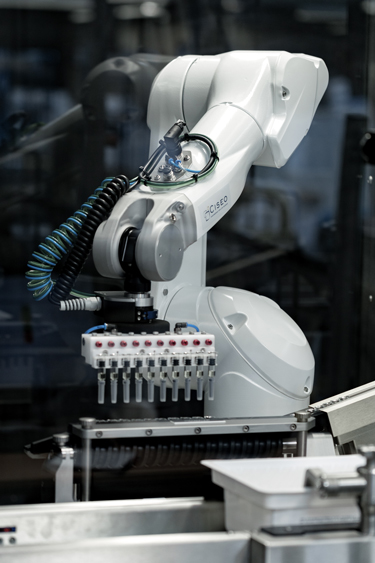

Starting from dedicated conveyors that separate the syringes and put them on a bucket chain (no-glass-to-glass technology), the RN150 recovers the syringes in order to store them accurately and safely in nests in line, thanks to its unique handling system. The nests are then placed in tubs, which are temporarily stored on an accumulation table at the exit. The RN150 has an average output of 150 syringes per minute, or 9,000 syringes per hour, and will fit perfectly into your production line.

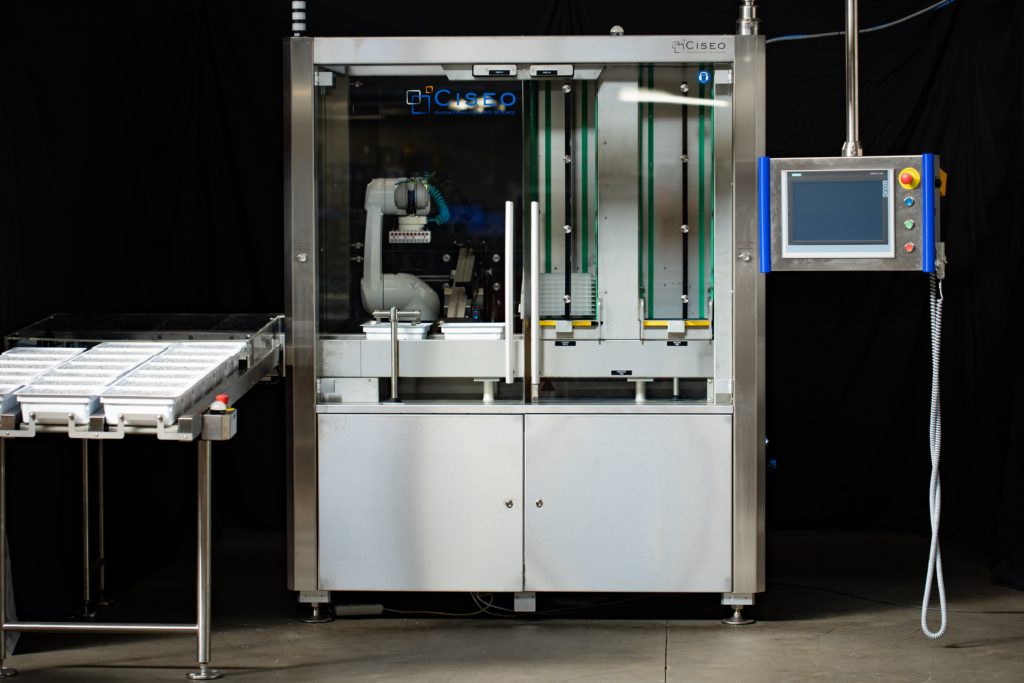

The RN150 automatic renesting machine perfectly satisfies the needs of the pharmaceutical industry: robust, compact, and harmoniously integrated into your production line.

It increases your company’s productivity, while guaranteeing the safety of your operators.

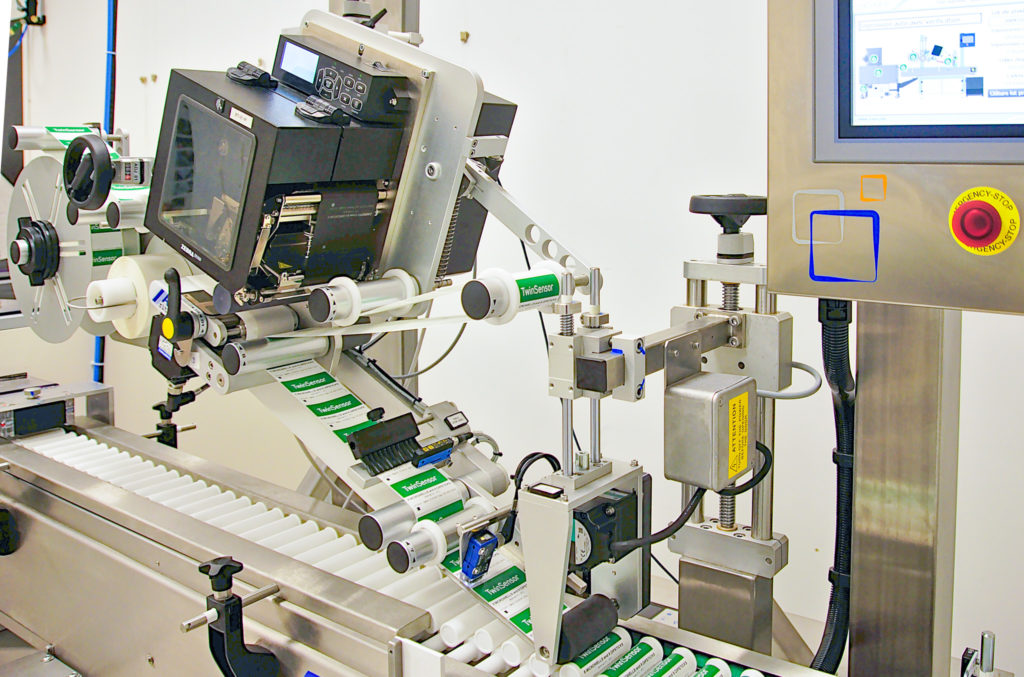

Your renesting machine is CE-certified and satisfies all the requirements of cGMP and GAMP5 good manufacturing practices.

| Elements | Processing range |

|---|---|

| Application | Pre-filled Syringes (PFS) |

| Format | Multiformats :

|

| Output | 150 syringes/min (9000 syringes /h) guarantee |

| Dimensions | 4714x1521mm |

| Frame | Inox 304/316L |

| Control Station |

|

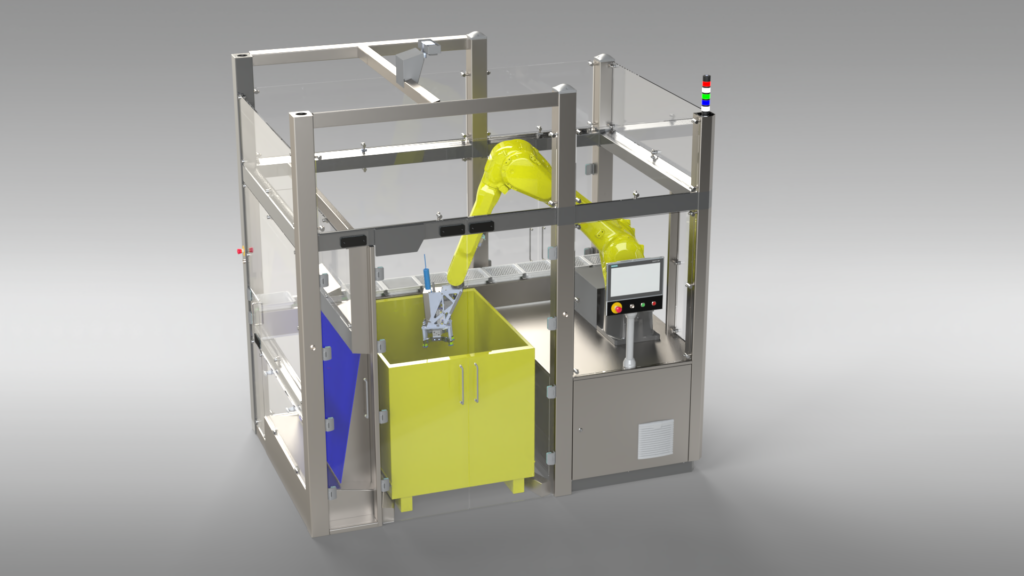

| Robot | STÄUBLI TX2 60L – CS09 (other robot on demand) |

| Électricity | 3 phases 400V – 25A – 50Hz |

| Pneumatic Pressure | 6 bars |

| Intégration |

|