Complex and fast distribution systems for various types of components

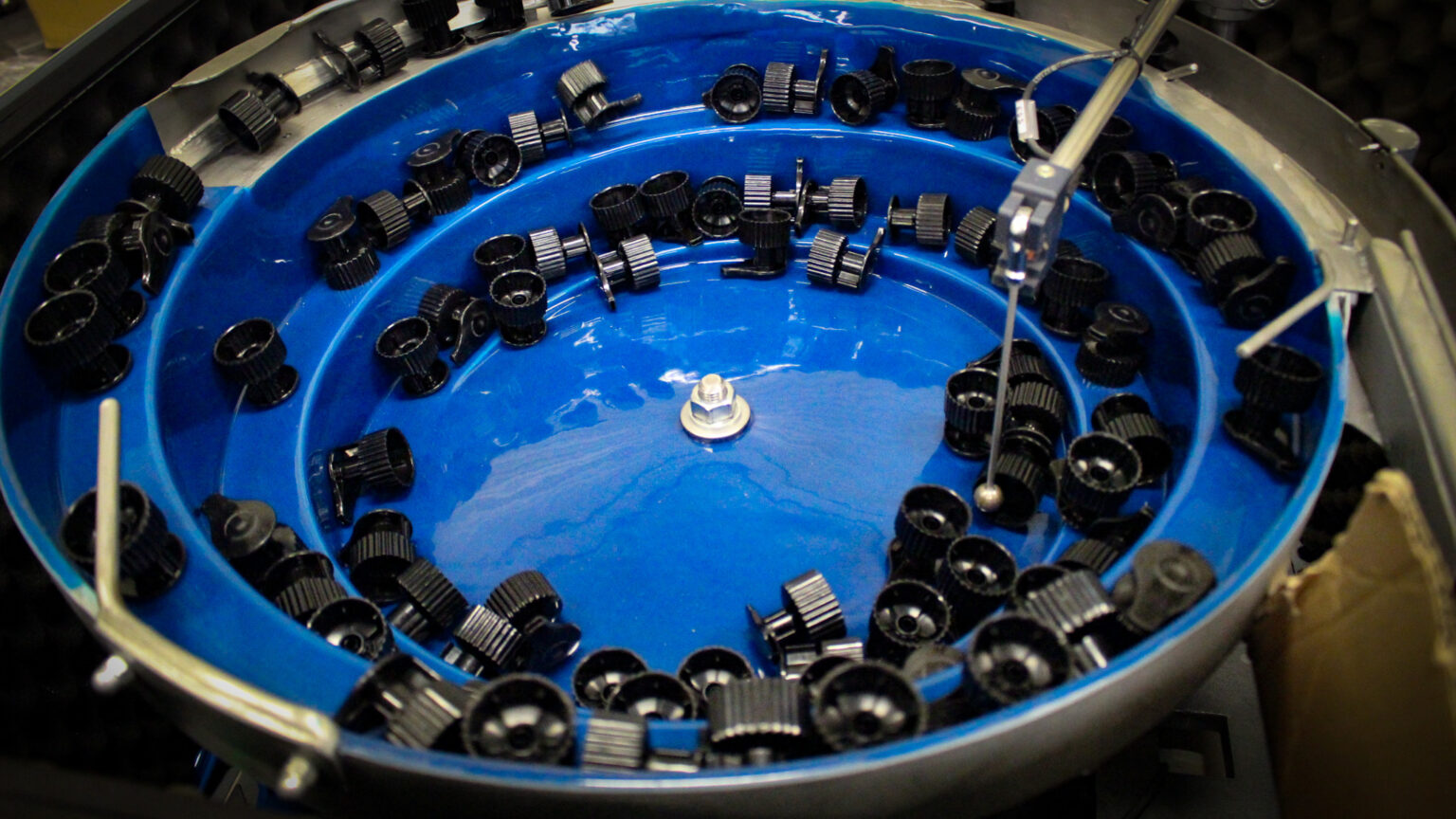

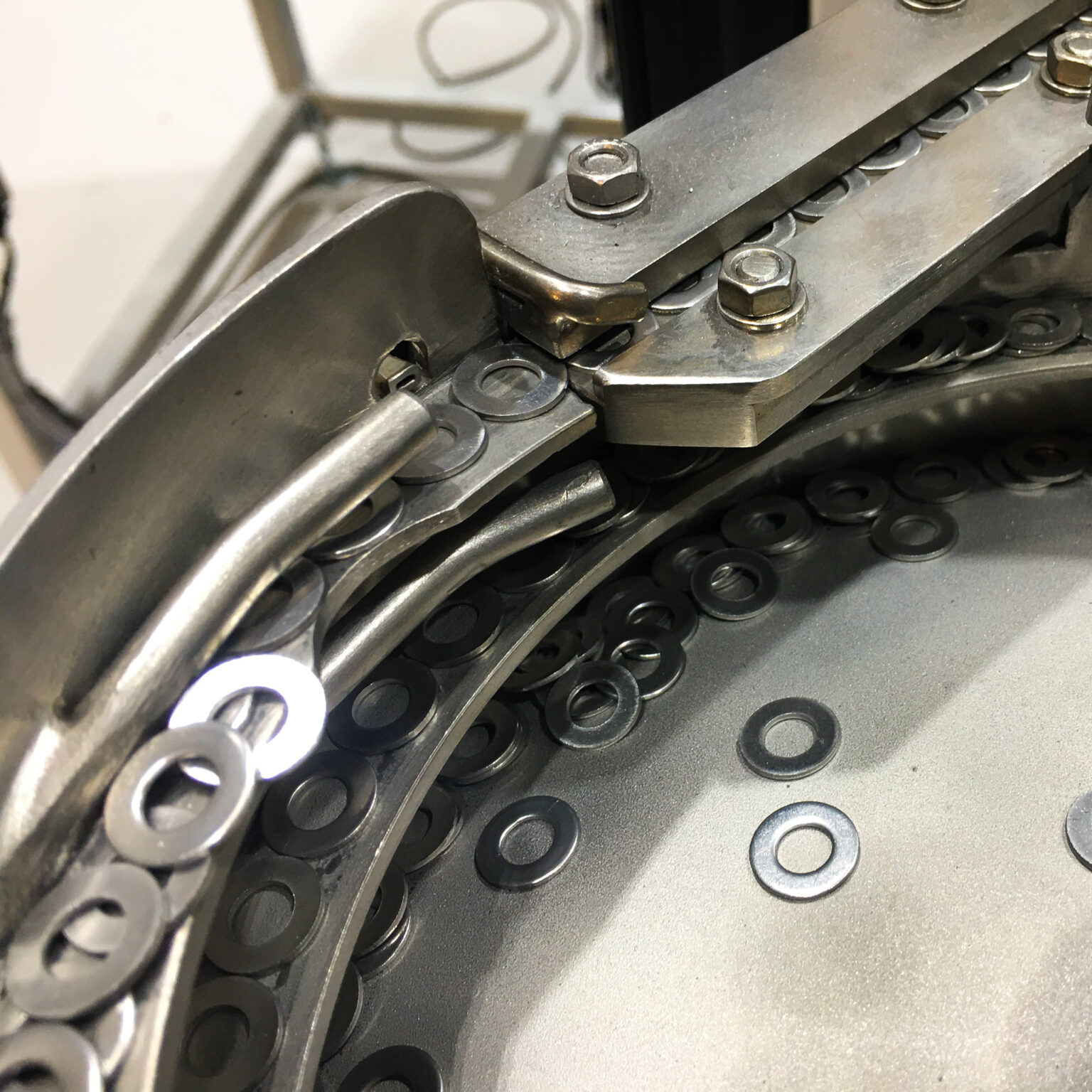

A bowl feeder is a type of feeder that consists of a bowl-shaped container that is designed to hold and feed small parts or components in a manufacturing or assembly operation. The bowl is mounted on a vibratory base, which causes the parts to move around the bowl and be presented at the feeder’s discharge point in a consistent and controlled manner. Bowl feeders are used in a wide range of industries, including automotive, electronics, and pharmaceuticals, and are commonly used to feed small parts such as screws, nuts, and pills. They are an efficient and reliable way to feed small parts, as they can handle a wide range of sizes and shapes and can operate at high speeds. Bowl feeders can be customized to meet the specific needs of different applications, and can be used in conjunction with other equipment, such as vision systems or robotic arms, to create a fully automated production line.

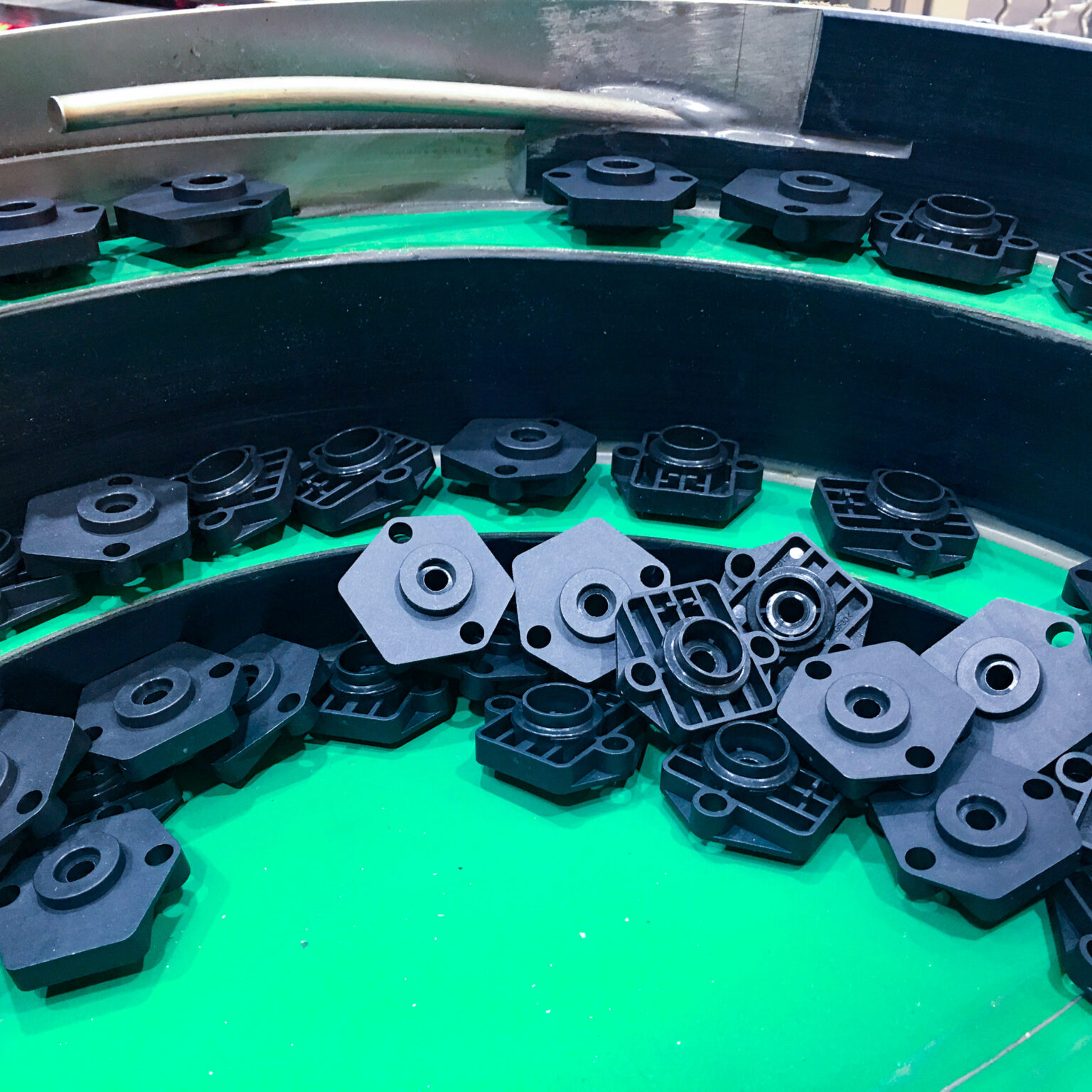

A centrifugal system has the same functionnalities as a bowl feeder but it uses centrifugal forces to move the parts. It is usually used for high throughput distribution of parts or components which can reach over 1000 units per minutes.